Professional Vehicle Wrap Installation: Techniques, Tools & Quality Standards

A vehicle wrap appears to be a creative decision from the outside. In reality, it behaves like an engineering project.

Most premature failures do not come from the vinyl itself. They show up because the surface was not prepared correctly, the film was overstretched, the edges were never post-heated, or the installer skipped “invisible” steps to save time. For a fleet or a single hero vehicle, that is the difference between a five-year mobile billboard and an expensive, short-lived experiment.

This guide is written for:

- Fleet managers and business owners who want to protect their investment

- Marketing teams that need a reliable partner for wraps

- Vehicle wrap installation experts who want to follow manufacturer-aligned best practices

The Science of Adhesion – Why Surface Prep Is Non-Negotiable

What Is Surface Energy, and How Does It Affect Wrap Adhesion?

Vehicle wrap films utilize pressure-sensitive adhesive (PSA) . That adhesive does not simply “stick” to anything you press it on. It needs a surface with enough surface energy for the glue to wet out and bond at a molecular level.

- Clean, cured automotive paint typically has a surface tension of 38–42 dynes/cm.

- Wax, silicones, traffic film, and ceramic coatings can reduce the coefficient of friction to below 30 dynes/cm.

On a low-energy surface, the adhesive beads up instead of flowing out. The wrap may look fine on day one, but the edges start to lift, bubbles appear around the trim, and the panels begin to shrink back long before the material’s rated lifespan is reached.

Professional installation starts with a simple principle:

Adhesion happens at the paint surface, not through a layer of wax, dust, or coating.

That is why every serious shop treats surface preparation as a multi-stage process, not a quick wash.

What Is a Proper 4-Stage Decontamination Protocol?

A professional installer does not rely on a hose and some soap. A wrap-ready vehicle passes through four distinct preparation stages:

- Chemical Degrease – Remove bulk grime and road film

- Use a pH-neutral automotive detergent that does not contain wax, gloss enhancers, or sealants.

- Rinse thoroughly, including wheel arches, lower rockers, and the area behind the trim where possible.

- Dry the vehicle thoroughly with clean microfiber towels.

- Use a pH-neutral automotive detergent that does not contain wax, gloss enhancers, or sealants.

- Mechanical Decontamination – Remove embedded particles

- Run a clay bar or clay mitt over all painted surfaces where vinyl will be applied.

- This lifts rail dust, brake dust, and overspray that regular washing leaves behind.d

- The test is simple: the surface should feel glass smooth, with no rough or gritty patches.

- Run a clay bar or clay mitt over all painted surfaces where vinyl will be applied.

- Molecular Stripping – Remove invisible hydrophobic barriers

- Wipe all wrap areas with a mix of isopropyl alcohol and water using clean, lint-free towels.

- Focus on panel edges, recesses, around handles, and badges.

- This step strips away silicones, light wax residues, and fingerprints that reduce surface energy.

- Wipe all wrap areas with a mix of isopropyl alcohol and water using clean, lint-free towels.

- Surface Energy and Primer – Prepare difficult substrates

- Areas such as unpainted plastics, textured bumpers, deep recesses, and rubber trims are naturally low-energy.

- A professional installer applies adhesion promoter sparingly on those edges and recesses.

- This increases local surface energy, allowing vinyl to maintain a secure bond through years of vibration and weather.

- Areas such as unpainted plastics, textured bumpers, deep recesses, and rubber trims are naturally low-energy.

For higher-risk projects, some shops also use dyne pens to verify that critical areas fall within the correct surface energy range before they unroll a panel.

When Should an Adhesion Promoter Be Used, And Where?

An adhesion promoter is not a magic bandage for poor prep. Used properly, it is a targeted tool for specific substrates and edge conditions.

Typical use cases:

- Inside deep body lines and recesses

- On unpainted plastics around bumpers and trims

- Along high-stress leading edges, such as hood lips and rocker panels

- Around door jambs and wheel arches, where dirt, water, and airflow concentrate

Best practice:

- Apply only to clean, dry, fully prepped surfaces

- Use a small applicator pad or cotton swab to apply the product precisely where needed.

- Avoid flooding large, visible areas, as the promoter can create a slightly darker “halo” under lighter colors.

The goal is not to replace adhesion; rather, it is to enhance it. It is to reinforce edges and low-energy spots that would otherwise become the first points of failure.

Professional Vehicle Wrap Installation Tools and Equipment

Professional Installation Tools and Equipment

A high-quality wrap is not just about the vinyl brand. It also depends heavily on the tools in the installer’s hands and how precisely they are used.

What Tools Do Professional Installers Use That DIY Kits Skip?

A professional toolkit typically includes:

- Multiple squeegee types with different hardness levels and felt buffers

- Knifeless tape for blade-free cutting along body lines and design transitions

- A digital heat gun or heat station with a stable output

- An infrared thermometer to verify surface temperatures

- Neodymium wrap magnets for panel positioning

- Clay bars, plastic scrapers, and detail brushes for prep

- Safety cutters are designed not to come into contact with paint.

DIY lists often mention “squeegee, knife, heat gun”. Professional setups take it a step further, focusing on control, repeatability, and risk reduction.

Why Does Heat Gun Quality Matter So Much?

Heat is one of the most abused variables in wrap installation. Too cold, and the adhesive never fully activates. Too hot and the film distorts, scorches, or shrinks prematurely.

A professional-grade heat gun:

- Provides a digital temperature readout rather than rough low/high” settings

- Maintains a stable output in the ideal range for cast vinyl during application

- Works well with an IR thermometer to check the actual panel temperature rather than guessing

Consistent heat makes it possible to:

- Pre-warm film before stretching on curves

- Post-heat edges and recesses to the target temperature band

- Avoid burning laminate, especially on chrome, textured, or specialty films.

It is not just about making vinyl softer. The goal is to control how the adhesive and film behave under stress.

How Does Knifeless Tape Protect OEM Paint?

Traditional trimming uses a utility blade along panel gaps and body lines. Even in skilled hands, that blade can nick clear coat, especially on curved surfaces or in awkward positions.

Knifeless tape solves that risk:

- It is applied to the vehicle before the vinyl, following the desired cut path

- Vinyl is laid over it and squeegeed in a usual manner.

- The installer pulls a filament inside the tape, which slices through the vinyl from the adhesive side.

- The tape itself is then removed, leaving a clean, precise cut with no blade contact on the paint.

Benefits:

- Strongly reduces the risk of cut marks and initiation points for rust.

- Allows complex design lines and color breaks that would be unsafe with a knife

- Creates a more consistent, repeatable finish for fleets or multi-vehicle runs

For business owners, knifeless tape is one of the simplest signs that an installer is committed to protecting your paint and maintaining its resale value.

What Other Quality Control Tools Should Be in the Bay?

Professional vehicle wrap installation bays usually also include:

- Infrared thermometer: to confirm post-heat temperatures on edges and recesses

- Bright, color-corrected lighting: to reveal contamination, silvering, and tiny bubbles before the vehicle leaves

- Clean stands and ladders: to access roofs and high panels safely without contacting the wrap with clothing or belts

- PPE and cleaning stations: so installers can work safely with solvents, primer, and heat

These details are rarely included in basic “how-to” guides, yet they have a direct impact on both finish quality and installer consistency from project to project.

Advanced Techniques That Separate Professional From “Good Enough”

Techniques that Separate Professional Vehicle Wrap Installers

Once prep and tools are in place, the difference between an average install and a long-lasting wrap comes down to tension control, air management, and film behavior on complex shapes.

What Is the Glassing Technique, And Why Does It Matter?

In complex areas like bumpers, curves, and recesses, an inexperienced installer often pulls vinyl tightly in one direction and chases wrinkles as they appear. This builds hidden tension into the film.

The glassing technique works differently:

- The film and panel are gently pre-warmed so the vinyl becomes more pliable

- The installer stretches the film only a small amount across the curve, often just a few percent.

- The vinyl is then allowed to relax, creating a smooth, “glass-like” surface that floats over the panel.

- Squeegee strokes start from a controlled anchor point, working the material into the shape without sudden pulls.

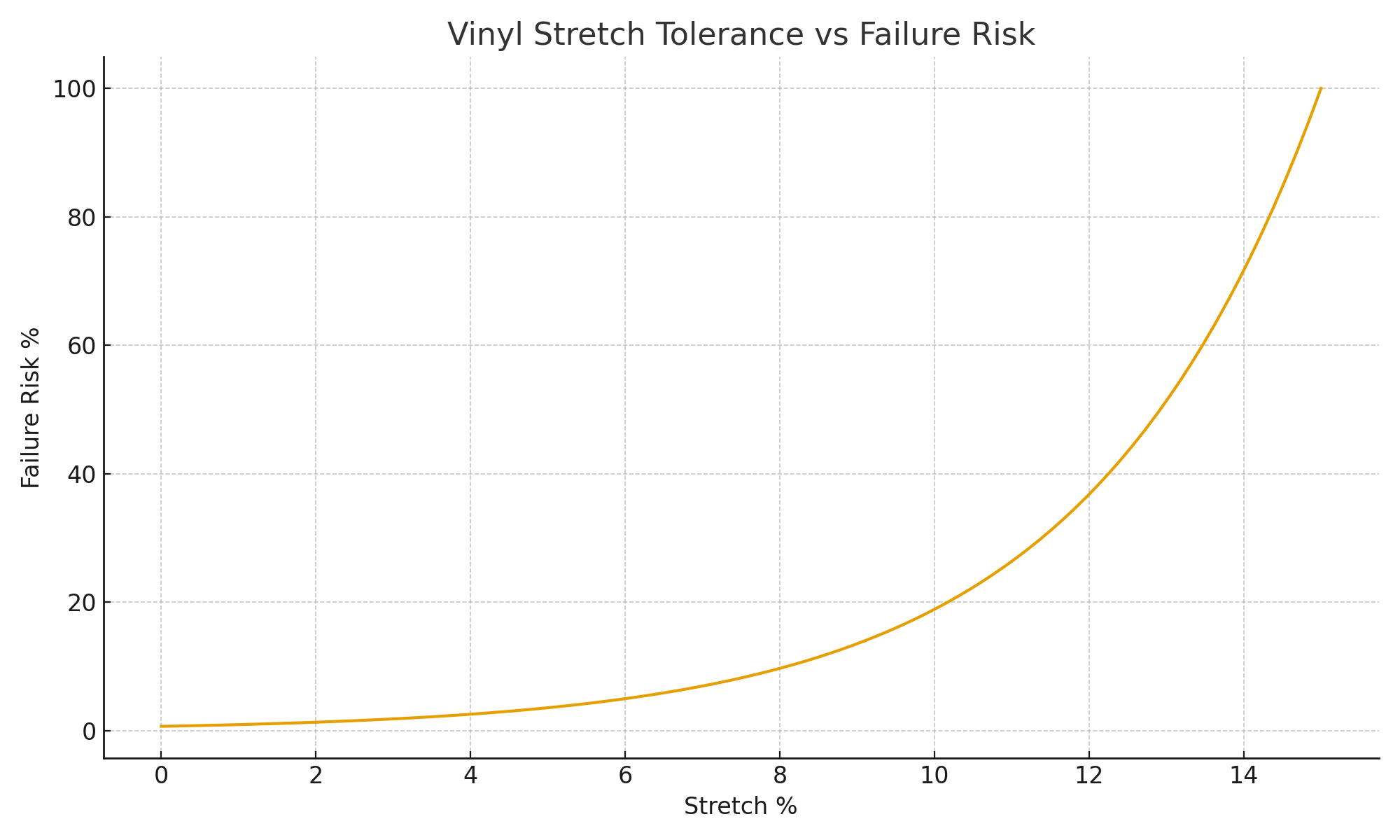

Vinyl Stretch Tolerance Vs Failure Risk

Benefits:

- Reduces the risk of whitening, where overstretched film thins out and lightens on dark colors

- Minimizes internal stress that would otherwise trigger shrinkage in the months ahead

- Creates smoother results around complex transitions such as bumper corners, fog light recesses, and wheel arch contours

Instead of forcing the film to obey, glassing invites it to settle into the shape with minimal tension.

How Do Professionals Manage Tension on Curves, Recesses, and Bumpers?

Every curve and recess wants to pull vinyl in several directions at once. Professional installers manage tension deliberately rather than reactively.

Common strategies include:

- Anchor points: Tacking portions of the panel first to control how material flows

- Tension triangles: Removing small wedges of excess film in waste areas so the graphic area lies flat

- Relief cuts in non-critical, hidden regions to prevent tension from building in visible surfaces

- Sequential application: Working on complex areas in a specific order instead of tackling everything at once

The rule of thumb is simple:

Wherever vinyl is being forced to bridge or drum over a gap instead of sitting in contact with the surface, tension exists, and failure will follow.

Good installers spend more time planning panel sequence and tension release than they do trimming the final edge.

How Do Air Release Channels and the Squeegee Technique Work Together?

Most modern cast wrap films incorporate air release channels into their adhesive. These micro-channels allow trapped air to escape rather than stay locked under the film.

They only work correctly with the proper squeegee method:

- Angle: Around 45 degrees to the surface, so the squeegee pushes both vinyl and air in a controlled direction

- Direction: From the center of the panel toward the edges, never random back and forth strokes

- Overlap: Each pass overlaps the previous one by roughly half the squeegee width

- Pressure: Firm and consistent, enough to collapse the channels but not so extreme that it distorts the film

If strokes are random or too light, air paths close in the wrong places, leaving pockets that appear as bubbles or silvering within hours or days.

Getting this right is less about strength and more about rhythm and consistency.

What Does a “Professional” Panel Alignment Look Like?

Panel alignment is about more than lining up a logo from one door to the next. A professional wrap installation will:

- Use consistent film orientation so metallics and pearlescent finishes reflect light the same way on each panel

- Plan seam locations in low-visibility areas, away from focal logos or key messaging.

- Avoid seams in high-stress zones such as deep recesses, tight curves, or near door handles.

- Keep any unavoidable seams tight, even, and post-heated adequately so they do not become early failure points.

For fleets, consistent alignment across vehicles tells your customers that the graphics are not an afterthought. They are part of a managed brand system.

Post-Heating and Thermal Stabilization – The Step That Separates Pros From Everyone Else

Post-Heating and Thermal Stabilization During Car Wrapping

Most wrap failures occur after the installation appears to be complete. Edges lift, corners peel, and recessed areas slowly shrink back. These are not material defects. They are results of skipping one critical final step:

Post-heating resets the vinyl’s internal memory and prevents shrink back for years.

Why Vinyl Has a “Memory Effect”

Vehicle wrap films are made from polyvinyl chloride (PVC). When PVC is stretched, the polymer chains pull in one direction, storing internal tension. Without thermal stabilization, that tension never goes away.

Symptoms appear weeks or months later:

- Edges curl backward

- Corners lift

- Door jamb areas release

- Recessed channels, tent, or split

- Seams widen

This is why professional installers never hand over a vehicle without evidence of proper post-heating.

Required Post-Heating Temperatures by Film Type

| Vinyl Type | Application Heat | Post-Heat Temperature | Purpose |

| Cast Vinyl (3M 2080, Avery SW900) | 100–120°F | 200–220°F | Eliminates memory effect |

| Calendered Vinyl | 120–140°F | 210–230°F | Reduces high-shrink tendencies |

| Textured/Carbon Fiber | 110–130°F | 200–215°F | Preserves texture while stabilizing |

| Chrome/Metallic | 90–110°F | 190–210°F | Prevent film damage while setting |

Necessary: The installer must heat the actual surface, not just the air. This is why IR thermometers are mandatory.

Proper Thermal Stabilization Technique

A professional workflow follows these steps:

- Allow vinyl to rest for 20–30 minutes after final squeegee sessions

- Heat 10–12-inch sections methodically

- Keep the heat gun 4–6 inches from the surface.

- Move in slow circles to avoid hot spots.

- Verify temperature with an IR thermometer.

- Apply gentle edge pressure while the vinyl is cool.

- Wrap edges at least ¾ inch around the backside.

- Complete a final heat pass around all trim lines and recesses to ensure a smooth finish.

Budget installers skip this because it adds 45–90 minutes to the job. That shortcut guarantees early failure.

Disassembly – The Only Way to Prevent Peel Points

Worker Wrapping Edges after Disassembling Front Bumper

A professional wrap does not simply go around obstacles; it effectively navigates them. It integrates behind them. That means disassembly is not optional.

The “Peel Point” Problem Explained

When vinyl is trimmed around:

- Door handles

- Mirror bases

- Emblems

- Trim pieces

…it leaves exposed micro-edges.

At highway speeds, airflow becomes a constant wedge that “picks up” the film. Once lifted, dirt and moisture slip underneath, and the bond never recovers.

Ninety percent of early failures originate from undisassembled edges.

What Gets Removed in a Professional Vehicle Wrap Installation?

| Component | Why Remove It? | Failure Prevented |

| Door Handles | Creates seamless door panels | Lifting around cups |

| Mirrors | Wrap the pillar without seams | Wind-driven edge lifting |

| Emblems/Badges | Avoid blade cutting around logos | Micro-tears, rust initiation |

| Tail Lights/Headlights | Wrap cleanly behind edges | Water intrusion |

| Plastic Trim | Wrap deeper into body lines | Dirt collection zones |

| Antennas/Accessories | Clear surface for tension control | Bridging and tenting |

Professional installers remove hardware. Budget installers wrap around it.

Forensic Defect Analysis – How Pros Audit a Wrap

Unlike competitors, BlinkSigns does not “eyeball it.” We use a structured defect classification system to catch and correct issues before the client ever sees the vehicle.

Most Common Vehicle Wrap Installation Defects and Their Causes

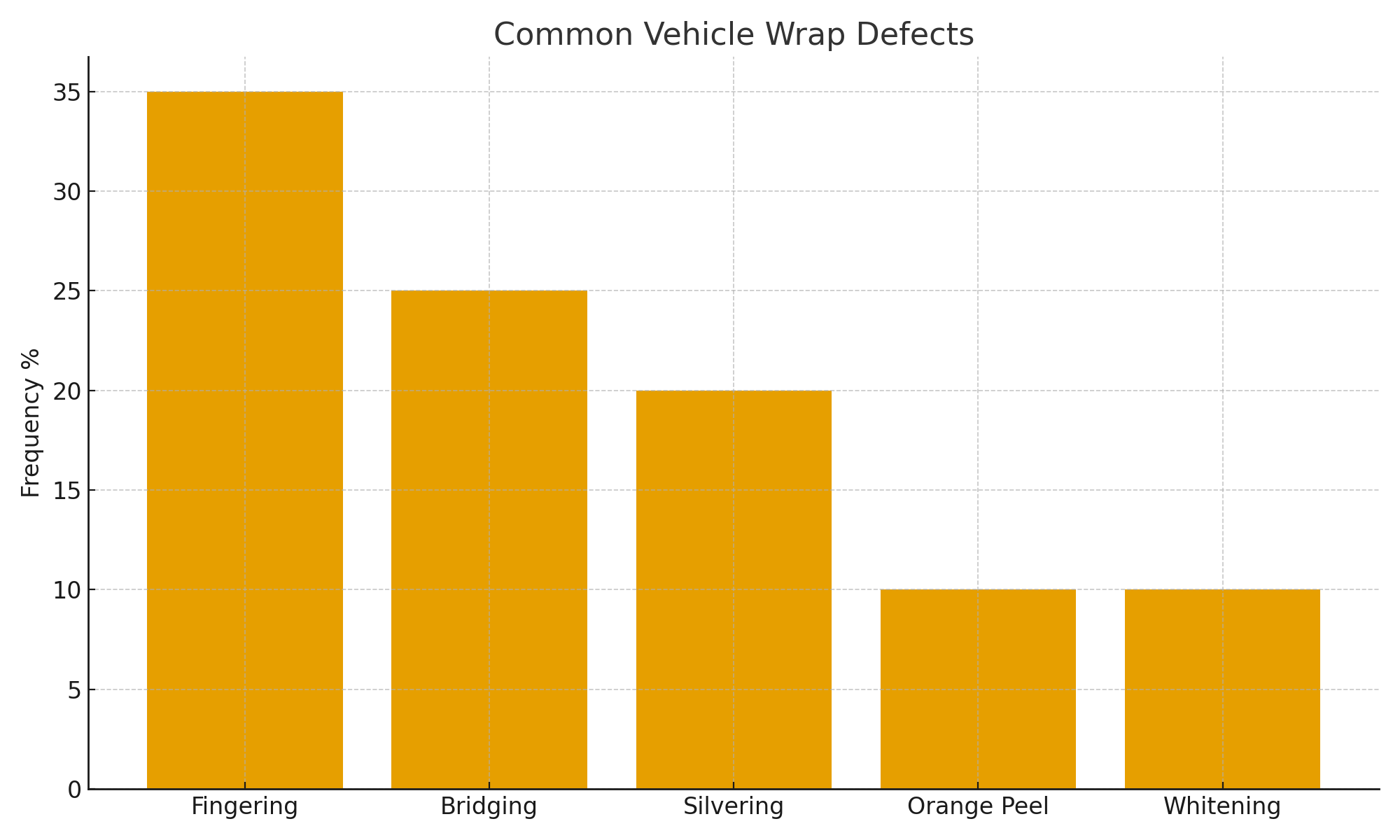

| Defect | Visible Symptoms | Primary Cause | When it shows | Warranty Status |

| Fingering (Edge Lifting) | Finger-shaped wrinkles on the edges | Poor post-heating / contaminated edges | 1–3 months | Not covered (installer error) |

| Bridging / Tenting | Vinyl “drums” over gaps | Not fed into recess | Immediate | Not covered |

| Silvering | Metallic air lines are visible | Cold install / weak squeegee pressure | Immediate–72 hrs | Maybe (if material related) |

| Orange Peel | Bumpy texture | Dirt in prep / overheated laminate | Immediate | Not covered |

| Whitening | Lightened color on curves | Overstretching | Immediate | 100% denied |

| Fish-Eyes/Bubbles | Random air pockets | Contamination / wrong technique | Immediate–7 days | Not covered |

Common vehicle wrap defects

BlinkSigns performs a 15-point forensic inspection before release, including edge adhesion, seam width, curve conformity, and post-heat verification.

3M MCS Warranty – The Certification That Actually Protects Your Money

Most shops claim to be “certified.” Few explain what that means financially.

Standard (Uncertified) Warranty vs 3M MCS Warranty

| Warranty Type | Material | Removal Labor | Re-installation Labor | Client Cost on Failure |

| Standard (Uncertified) | ✔ Covered | ✘ Not covered | ✘ Not covered | $3,000–5,000 |

| 3M MCS Warranty | ✔ Covered | ✔ Covered | ✔ Covered | $0 |

Only 3M Preferred Installers can offer full labor-included warranties.

This is why commercial fleets choose certified shops. It eliminates financial exposure due to installation-related failures.

Why Most Warranty Claims Get Denied

Manufacturers deny claims when:

- Vinyl shows overstretch whitening

- Post-heating temperatures were never achieved.

- Primer was not used on low-energy areas.

- Workspace humidity was too high.

- Vehicle had uncured paint (outgassing bubbles)

- The wrong material was used for the body shape.

BlinkSigns documents:

- Temperature logs

- Humidity & environment data

- Surface preparation steps

- Material batch numbers

- Pre- and post-installation photographs

This creates audit-proof warranty protection.

Installation Environment – The Bay Matters As Much As the Tools

Required Conditions for Professional Installation

| Variable | Professional Standard | If Ignored |

| Temperature | 60–80°F | The adhesive fails to wet out |

| Humidity | <60% | Moisture trapping → bubbles |

| Lighting | ≥1000 lumens, 5000K color | Missed defects |

| Dust Level | Clean, enclosed bay | Orange peel, contamination |

| Surface Temperature | ≥68°F | The adhesive does not activate |

Any installer working outdoors or in uncontrolled garages is risking the entire wrap.

BlinkSigns installs in a climate-controlled facility year-round.

Fleet Downtime and ROI — Why Professional Installation Saves Money

Flaws are not just cosmetic. They affect revenue.

The Hidden Cost of Downtime

Most businesses underestimate vehicle downtime:

- Delivery vans: $800–1,200 per day

- Service trucks: $1,500–2,500 per day

- Sales vehicles: $500–800 per day

A cheap wrap that fails after 18 months requires:

- Removal (1–1.5 days)

- Re-wrap (2–3 days)

Total downtime cost: $2,400–7,500 per vehicle.

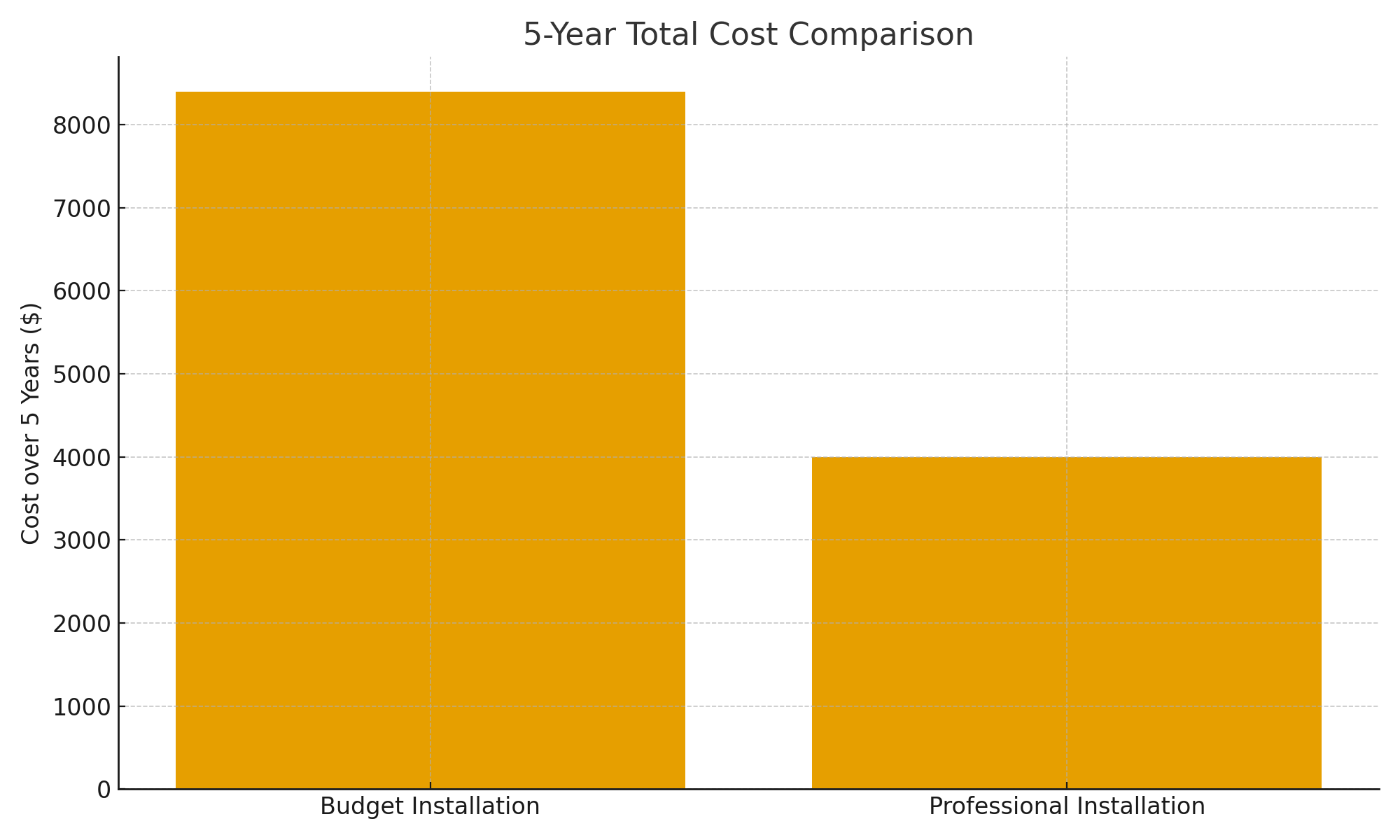

5-Year Total Cost of Ownership Comparison

5 year total cost comparison

Budget Installation Path

- $2,500 initial

- $500 removal after failure

- $2,500 re-wrap

- $2,400–7,500 downtime

Total: $8,400–12,000 over 5 years

Professional Installation Path

- $4,000 initial

- MCS warranty covers defects

- No re-wrap costs

- Zero downtime from failure

Total: $4,000 over 5–7 years

Real ROI: Professional installation costs approximately $2.20 per day, while budget installs cost $4.60–$ 7.50 per day.

Frequently Asked Questions

Q1: How long does a professional wrap installation take?

A fully compliant installation takes 2–3 days, depending on surface preparation, hardware removal, compaction preparation, and post-heating.

Q2: What makes certified installation different?

Certified installers follow manufacturer-approved techniques and can offer full labor warranties. Uncertified shops cannot.

Q3: Why do edges lift after a few months?

Edge lifting occurs when installers skip post-heating, fail to remove contaminants, or wrap too shallowly around edges.

Q4: Can I wrap a freshly painted vehicle?

No. Paint must cure for 30–90 days, or gases trapped beneath he wrap will create bubbles.

Q5: What conditions must a wrap bay meet?

Stable temperature, low humidity, dust-free environment, and intense lighting. Outdo, or in intention, voids warranties.

Q6: Do you remove door handles, mirrors, and badges?

Yes. It prevents ts peel points and dramatically extends wrap lifespan.

Q7: Do professional wraps harm the paint?

No. They protect OEM paint, provided the prep work with the knifeless tape is done correctly.

Q8: How long does a professional wrap last?

Typically, 5–7 years, provided the installation and maintenance are correct.

Q9: What maintenance is recommended?

Hand wash only; avoid automatic washes and pressure jets. Also, inspect edges and do so annually.

Q10 What is the biggest mistake budget installers make?

Skipping post-heating, stretching vinyl too aggressively, and avoiding disassembly to save time.

Conclusion

Professional vehicle wrap installation is not just a craft; it’s a highly skilled endeavor. It involves chemistry, physics, skill, and quality engineering conducted under controlled conditions. When surface preparation, tension management, thermal stabilization, and certified techniques come together, a wrap delivers its whole 5–7 year lifespan.

BlinkSigns’ team, which is certified in two areas, follows set manufacturer guidelines, works in controlled environments, and conducts thorough inspections to make sure the wrap you buy lasts a long time.

Contact us today: +18774334466