Fleet Branding Strategy: How to Maintain Consistency Across Multiple Vehicles

When Your Fleet Sends Mixed Messages

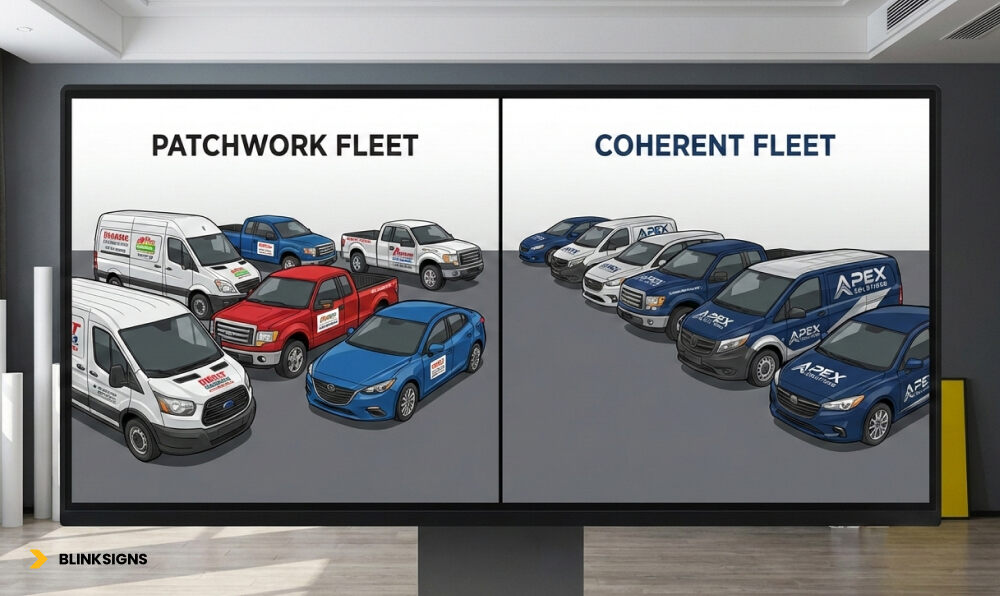

Your vehicles are often the first real-world touchpoint a customer sees. A clean van with sharp graphics says, “We’re organized and reliable.” A lineup of mismatched trucks—different blues, old logos, clashing layouts—quietly says the opposite.

Most companies don’t set out to create an inconsistent fleet. It happens slowly:

- One region “updates” the logo on its own

- A new installer picks almost the right shade of blue vinyl.

- A leased truck gets a stripped-down version “just for now.”

Five years later, the fleet resembles three distinct companies on the road.

This article demonstrates how to transform fleet branding into a governed system, rather than a series of one-off wrap projects. The focus is practical:

- Fleet-specific brand guidelines (beyond your general brand book)

- Color matching protocols across vendors and regions

- Scalable designs that work on sedans, vans, box trucks, and trailers

- Rollout frameworks that keep things under control as you grow

Throughout, we’ll examine branding from a fleet manager + brand manager point of view: how to protect brand equity, minimize rewrap waste, and keep every vehicle on-message for 5–7 years.

Why Fleet Branding Consistency Matters

How repetition builds brand recall on the road

Marketing teams talk about reach and impressions. Fleet managers talk about uptime and utilization. Fleet branding sits right between the two.

Research on brand recall indicates that people typically need to see a brand 5–7 times before they can recall it. A strategic fleet acts like a rolling media network:

- A single van may generate tens of thousands of impressions per month in its territory

- A 30–50 vehicle fleet can quietly dominate local visual real estate.

- Consistent colors, logos, and layouts turn those touchpoints into a pattern people recognize

The key is repetition plus sameness. When every vehicle looks clearly related, each sighting reinforces the previous one. The brain starts to file your brand under “familiar,” which is a shortcut to trust.

How inconsistent vehicles quietly erode trust

Customers rarely email to say, “Your trucks don’t match.” They just feel it.

Standard signals that something’s off:

- Three different blues for the “same” brand color

- Old and new logos are still in circulation.

- Different phone numbers or URLs for similar vehicles

- Layouts that vary wildly from region to region

For buyers, this can trigger questions:

- “Are these the same people I saw last week, or a different outfit?”

- “If they can’t control their own brand, will they manage my project details?”

Inconsistent fleet branding doesn’t just look messy; it suggests inconsistent processes behind the scenes, particularly for service businesses that rely on trust—such as HVAC, plumbing, logistics, and healthcare—where those subtle visual cues matter.

Consistency as a signal of operational reliability

A disciplined fleet look does more than please designers:

- Shows operational discipline – every region follows the same playbook

- Supports safety and compliance – required markings are clearly visible and consistently applied.

- Makes internal management easier – new vehicles slot into a defined visual system.

- Strengthens recruitment and pride – drivers like being seen in professional vehicles

A consistent fleet becomes a brand asset you can scale and measure, rather than a collection of rolling exceptions.

patchwork fleet vs. a coherent fleet

Building a Fleet Brand System, Not Just a Wrap Design

Most companies already have a brand guidelines PDFs that covers logo usage, colors, and fonts. The problem: those documents rarely get specific about vehicles, and installers often improvise.

A serious fleet program requires fleet-specific brand guidelines that transform your visual identity into precise, repeatable rules for wraps and graphics.

What goes inside fleet-specific brand guidelines?

A good fleet brand guide reads like a playbook, not a mood board. At a minimum, it should cover:

- How the logo appears on each vehicle type

- Exact color specifications and vinyl film equivalents

- Typography rules that consider viewing distance at speed

- Messaging hierarchy when space is tight vs. abundant

- Rules for scaling layouts from a sedan to a trailer

- Expected standards for materials, installation, and QC

These guidelines give installers less room to “interpret” the brand and more reason to follow a proven system.

Logo, color, type, and messaging rules for vehicles

Vehicle graphics aren’t print ads. People see them:

- From 20–50+ feet away

- At 30–60 mph

- Often for 2–3 seconds at a time

That reality changes how you set rules.

Logo rules:

- Minimum widths by vehicle type (e.g., 12” on sedans, 24” on vans, 36 “+ on box trucks)

- Approved placements: driver/passenger doors, rear doors, trailer sides

- Clear space around the logo so it never competes with photos or text

- “Never” list: no stretching, skewing, drop shadows, or recolors

Color rules:

- Brand colors are defined in Pantone, CMYK, RGB, and HEX

- Vinyl film equivalents for 3M / Avery / Orafol

- Contrast rules, e.g., 70%+ luminance contrast between background and text

Typography rules:

- Primary and secondary fonts, with minimum letter heights for phone, URL, tagline

- Restrictions on weights: bold for headlines, regular for details, no ultra-light styles

- Simple typographic hierarchy: brand name > main message > contact information

Messaging rules:

- Must-have elements: logo, company name, phone number, website

- Optional elements depending on space: tagline, three key services, QR code, review stars

- Character limits prevent vehicles from becoming unreadable word walls.

How to keep guidelines usable as your fleet grows

Guidelines only work if people use them. To keep them practical:

- Keep the main guide in the 15–20 page range with visuals, not dense text

- Offer a one-page cheat sheet per vehicle type for quick reference.

- Version your guide (v1.0, v1.1, etc.) so everyone knows what’s current.

- Store everything in a central “fleet brand hub” and share only through that channel.

Below is a concise snapshot of what the fleet guideline document should include.

Fleet Vehicle Brand Guidelines: Key Sections

| Section | What It Covers | Why It Matters |

| Brand Overview | Mission, values, positioning, tone of voice | Aligns fleet visuals with the overall brand story |

| Logo Specifications | Sizes, clear space, placement by vehicle type | Prevents distorted or poorly placed logos |

| Color Palette | Pantone, CMYK, RGB, HEX, vinyl film equivalents | Keeps colors consistent across vendors and regions |

| Typography | Font families, weights, minimum sizes, spacing | Ensures legibility at real driving distances |

| Messaging Hierarchy | Must-have and optional copy elements | Avoids clutter; keeps focus on what matters most |

| Scalability Framework | Rules for adapting designs across vehicle sizes | Gives installers a system for mixed fleets |

| Vendor Standards | Approved materials, certifications, processes | Raises baseline quality for every install |

| QC Checklist | Pre-production and post-installation checks | Catches issues before vehicles go back on the road |

| Maintenance Protocol | Washing, inspections, and replacement triggers | Extends lifespan and retains a consistent look |

| Rollout & Governance | Pilot, regional rollout, approvals, version control | Stops “one-off” designs and rogue local changes |

Fleet Branding guideline

Color Matching and Material Standards Across Vendors

Even with perfect layouts, your fleet will still look off if blues, reds, and grays shift from vehicle to vehicle. This happens more often than most brands realize.

Why does the same brand blue look different on different vans

Color inconsistency comes from a mix of variables:

- Different vinyl films and inks

- Different printers and calibration settings

- Different laminates and surface textures

- Vehicles approved under indoor light, then seen in outdoor daylight.

The result:

- A “strong corporate blue” that appears navy on some trucks and electric on others

- A gray that reads slightly green in one region and somewhat brown in another

For a national or regional fleet, that’s a direct hit on perceived quality.

Pantone, vinyl film numbers, and Delta E thresholds

Brand teams often specify colors only in Pantone or CMYK, but vinyl manufacturers speak a slightly different language: film numbers.

To bridge that gap:

- Map each brand color to specific film numbers (3M, Avery, Orafol, etc.)

- Require vendors to use those films, not “closest match” alternatives.

- Measure differences using a spectrophotometer and ΔE (Delta E), not just the naked eye

A practical standard many programs use:

Delta E ≤ 2.0 between the approved master swatch and any vendor sample.

Below that threshold, most people can’t see the difference.

A 7-step color matching protocol for fleets

A simple, repeatable protocol could look like this:

- Establish master color standards

- Define each color in Pantone, CMYK, RGB, and HEX.

- Print master swatches on approved vinyl + laminate, not just on paper.

- Store a physical “swatch deck” as the single source of truth.

- Specify vinyl film equivalents.

- Create a table with the Pantone color number → 3M / Avery / Orafol film numbers.

- Flag any colors requiring a custom mix or special approval.

- Set vendor calibration requirements.

- Vendors must use a spectrophotometer to verify their colors against the master swatches.

- Require documentation of printer profiles and settings.

- Use a formal print proof process.

- Vendors send 12” x 12” drawdown swatches for each key color.

- The brand/fleet team compares visually and with ΔE measurement.

- Approve or request adjustments before any complete runs.

- Standardize lighting for approvals.

- Evaluate samples under D65 daylight-equivalent light.t

- Spot-check under office light and outdoor sun to catch metamerism

- Synchronize multiple vendors

- Name one lead partner responsible for setting master standards.

- Share physical swatches and ICC profiles with regional installers.

- Audit the first production batch from each region.

- Maintain and refresh standards.

- Reprint master swatches annually, primarily for sun-exposed fleets.

- Run random checks on existing vehicles against swatche.

- Document any deviations and corrections.

To make this actionable, your guidelines should include a simple color reference table.

Color Matching Summary

| Brand Color | Pantone | 3M Film # | Avery Film # | Orafol Film # | ΔE Target | Approval Process |

| Primary Blue | PMS 286 | 3M Scotchcal 7125-15 | Avery 700-421-O | Orajet 970-216 | ≤ 2.0 | Vinyl drawdown, spectrophotometer + visual check |

| Primary Red | PMS 185 | 3M Scotchcal 7125-13 | Avery 700-318-O | Orajet 970-031 | ≤ 2.0 | Visual match in D65 light, confirm with measurement |

| Secondary Gray | Cool Gray 10 | Custom mix | Avery 700-935-O | Orajet 970-935 | ≤ 2.0 | Pre-production approval is required for each vendor |

Color Matching and Material Standards Across Vendors

Designing for Mixed Fleets: A Scalability Framework

Very few fleets are made of a single vehicle type. More often, you see a mix:

- Sales sedans

- Service vans

- Box trucks or step vans

- Occasionally, trailers or tractors

A design that looks powerful on a 26-foot box truck often looks cramped or chaotic on a compact car. The answer is not a hundred one-off designs; it’s a scalability framework.

Core, expanded, and full-story design tiers.

An easy way to think about scalability:

- Tier 1 – Core Brand

For smaller vehicles with limited space- Logo

- Company name

- Phone number

- Website

- Tier 2 – Expanded Message

For mid-size vehicles- Tier 1 elements, plus:

- Short tagline

- Up to 3 key services

- Tier 3 – Full Brand Story

For large and extra-large vehicles- Tier 2 elements, plus:

- Product/service imagery

- Trust signals (years in business, review stars, accreditations)

- QR code and/or social handles

Every vehicle carries the same core identity, but larger surfaces tell more of the story.

Mapping designs to vehicle categories

You can tie tiers directly to vehicle categories:

- Category A – Small

Sedans, compact cars (30–50 sq ft graphic area) → Tier 1 - Category B – Mid-Size

SUVs, pickups, cargo vans (100–150 sq ft) → Tier 2 - Category C – Large

Box trucks, step vans (300–500 sq ft) → Tier 3 - Category D – Extra-Large

Semi-trailers (600–1,000+ sq ft) → Tier 3 with extended storytelling

This prevents the common mistake of trying to force a trailer layout onto a sedan or leaving big trucks looking oddly empty.

Logo size and legibility rules that scale

Two simple formulas help keep things readable and consistent:

- Logo coverage rule

- The logo should occupy roughly 15–25% of the largest flat panel.

- On a small sedan side panel with an area of 8 sq ft, that means ~1.2–2 sq ft of logo area.

- On a 60 sq ft box truck side panel, that means ~9–15 sq ft.

- Text legibility rule

- Approx. 1” of letter height per 25 feet of viewing distance

- Phone number legible from 50 ft → 2” letters or more

- Website legible from 30 ft → ~1.25–1.5″ letters

- Tagline legible from 40 ft → ~1.75–2″ letters

These numbers are included in your guidelines as non-negotiable specifications.

Design Tiers by Vehicle Category

| Category | Typical Vehicles | Approx. Graphic Area | Design Tier | Required Elements | Optional Elements |

| A: Small | Sedans, compact cars | 30–50 sq ft | Tier 1 | Logo, company name, phone, website | None (keep layout clean and bold) |

| B: Mid | SUVs, pickups, cargo vans | 100–150 sq ft | Tier 2 | Tier 1 + short tagline, up to 3 key services | QR code, secondary contact method |

| C: Large | Box trucks, step vans | 300–500 sq ft | Tier 3 | Tier 2 + product/service imagery, trust signals | Social handles, larger copy-based CTA |

| D: XL | Semi-trailers, tractor–trailer combos | 600–1,000+ sq ft | Tier 3+ | All Tier 3 + extended brand story or campaign | Multiple scenes, storytelling panels, QR, etc |

Multi-Site Rollout: From Pilot Vehicles to a Fully Consistent Fleet

Fleet branding consistency breaks down when local teams make isolated decisions. The solution is a phased rollout system that aligns every region, installer, and vehicle under a single playbook.

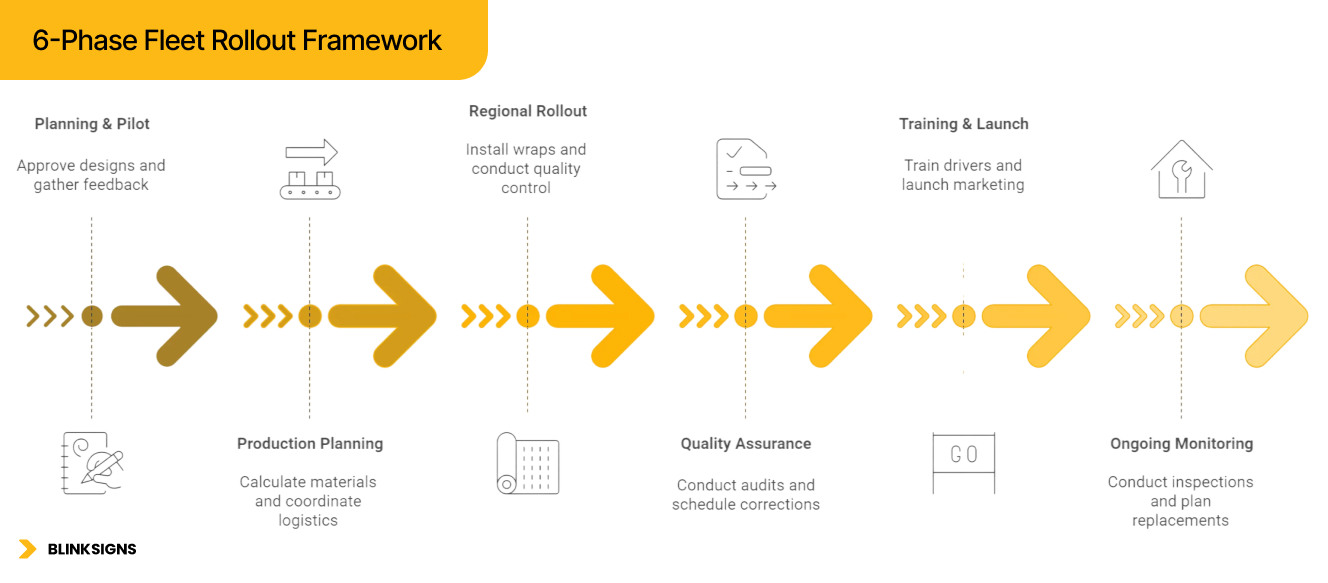

Below is the operational blueprint BlinkSigns uses when managing multi-location or multi-state fleets.

Start with a Pilot Fleet (2–5 Vehicles)

A pilot prevents costly mistakes across the whole fleet. It gives your team a chance to test:

- Brand visibility at different distances

- Legibility of phone numbers, URLs, and taglines

- Color consistency under real outdoor lighting

- Installer accuracy in following the guidelines

- Driver experience (door function, window perf, visibility, mirrors)

Typical pilot duration: 2–4 weeks

Pilot feedback sources:

- Drivers

- Dispatchers

- Field supervisors

- Marketing leadership

- Random public impressions (“What do people think when they see this?”)

If the design performs well in real-world environments, it becomes the master-approved design.

Regional Rollout Framework (10–12 Weeks)

Once the pilot is approved, the rollout expands in a structured series of phases.

Rollout Sequence Example

- Weeks 1–2 → Northeast region (high-visibility priority vehicles first)

- Weeks 3–5 → Southern region

- Weeks 6–8 → Midwest region

- Weeks 9–12 → West region

Recommended installation pace:

- 5–7 vehicles per week per installation team

- 1–2 days of downtime per vehicle

A region-by-region sequence prevents operations from collapsing due to an excessive number of vehicles being off the road.

6-Phase Fleet Rollout Framework

This framework is built for fleets ranging from 20 cars up to 300+.

| Phase | Duration | Key Actions | Deliverables |

| Phase 1: Planning & Pilot | 4 weeks | Approve final designs, wrap 2–5 pilot vehicles, gather feedback | Master design files; fleet brand guidelines |

| Phase 2: Production Planning | 2 weeks | Calculate material requirements; batch printing; coordinate shipping | Production calendar, logistics plan |

| Phase 3: Regional Rollout | 10 weeks | Install wraps in waves by region; QC each vehicle | Weekly rollout reports + photo documentation |

| Phase 4: Quality Assurance | 2–4 weeks | In-person audits of 20% of fleet; corrections scheduled | Audit report + corrected vehicles |

| Phase 5: Training & Launch | 2 weeks | Train drivers on cleaning and maintenance, launch marketing campaign | Driver handbook, internal rollout announcement |

| Phase 6: Ongoing Monitoring | Annual | Quarterly inspections; annual fleet audit | Condition reports + replacement roadmap |

6-Phase Fleet Rollout Framework

Quality Control and Maintenance for Long-Term Consistency

Even perfect design systems fail if QC is weak. Fleet QC has maintained consistent branding for over 7 years, not just at installation.

Per-Vehicle QC Checklist (Immediately After Installation)

Technicians and project managers check:

Visual Consistency

- Logo sized precisely as per the template

- Correct brand colors (compared to swatch book)

- Required elements present (logo, company name, phone, website)

Installation Quality

- No bubbles/wrinkles over 3mm

- Panel seams aligned

- All edges fully sealed

- No paint damage

Safety & Legibility

- Phone and URL readable at required distances

- DOT markings unobstructed

- Reflective markings (if required) installed correctly

Documentation

- Photos captured: front, back, passenger, driver, close-up logos, close-up text.

- Vehicle ID, install date, installer name, materials used

QC Checklist Snapshot

| Category | Checkpoint | Acceptance Criteria |

| Visual Consistency | Logo size accuracy | Within ±5% of template |

| Brand Colors | Match to vinyl swatch | No visible shift |

| Required Elements | Logo, phone, website | All present |

| Installation Quality | Bubbles/wrinkles | None > 3mm |

| Seams & Edges | Proper alignment & sealing | 100% secure |

| Legibility | Phone number readability | Clear at 50 ft |

| Safety | DOT/Regulatory items | Unobstructed |

| Documentation | Photo set | All angles submitted |

Fleet-Level Annual Audits

This maintains the overall health of the system across all regions.

Audit Scope

- Spot-check 20% in person

- Full photo review of 100% of the fleet

- Consistency grading (1–10 scale)

Common Issues Found

- Slight fading or inconsistent laminates

- Unapproved local modifications (“We thought adding our local number was fine”)

- Installer shortcuts (edges not sealed, missed heating)

Replacement Triggers

- Fading > 20%

- Edge lifting > 6 inches

- Brand update or rebrand

- Major graphics damage

Maintenance Protocols That Protect Wrap Lifespan

To maintain a uniform fleet look, maintenance rules must be standardized.

Cleaning Rules

- Hand wash only

- pH-neutral soap

- Avoid pressure washers on edges.

- No automatic car washes

Inspection Rules

- Monthly visual check by drivers

- Quarterly inspection by fleet manager

- Annual professional audit

Repair Rules

- Minor repairs: 7–14 days

- Significant damage: 3–5 days

- Emergency replacements: prioritized regionally

This prevents regional fleets from drifting apart in quality.

Technology, Tracking & Brand Governance

A fleet branding program only scales if information stays centralized and consistent.

The Fleet Brand Hub (Digital Governance System)

All brand assets live in a single secured repository:

- Fleet brand guidelines

- Vehicle templates (AI/PDF files)

- Pantone + vinyl swatch references

- ICC printer profiles

- Installation instructions

- QC forms

- Maintenance policies

Access levels:

- Marketing team

- Fleet managers

- Approved install partners

This eliminates “wrong logo file” problems.

Fleet Tracking Database

Every vehicle tracked in a database (Spreadsheet, Airtable, or dashboard):

| Vehicle ID | Type | Location | Install Date | Vendor | Condition Score | Next Inspection |

| VAN-001 | Transit Van | Chicago | Jan 2024 | BlinkSigns | 9/10 | Apr 2026 |

| TRK-027 | Box Truck | Dallas | Feb 2024 | Regional Installer | 7/10 | May 2026 |

This enables predictive maintenance and consistency checks.

Seasonal & Promotional Overlays

Your fleet can support campaigns without breaking consistency rules.

Base Wrap (Unchanging 5–7 years)

- Logo

- Brand colors

- Mandatory messaging

- Main layout

Seasonal Overlay Zones (1–6 months)

- Lower door strip

- Rear quarter panels

- Rear window (perforated vinyl)

Rules:

- Never cover the logo

- Never alter brand colors.

- Never replace the phone or website.

This allows seasonal promos without sacrificing identity.

The Real Cost of Inconsistency – ROI Breakdown

Companies often think consistent fleet branding is “expensive.” In reality, inconsistency is far more costly over time.

5-Year TCO Comparison (50-Vehicle Fleet)

| Scenario | Year 1 Cost | Hidden Costs (Years 1–5) | Total 5-Year Cost |

| Systematic & Consistent | $175,000 | $6,000 (minor repairs) | $181,000 |

| Ad-Hoc & Inconsistent | $133,000 | $85,000 (rewraps, failures, mismatched vendors) | $218,000 |

| Difference | Looks cheaper by $42,000 | Actually wastes $79,000 | Costs 20% more |

Hidden Costs in Inconsistent Fleets

- Rewrapping mismatched colors

- Fixing incorrect placements

- Reinstalling poor-quality wraps

- Operational downtime

- Weak brand visibility due to inconsistent layouts

Consistent fleet branding is not an expense; it’s a cost-saving system.

Frequently Asked Questions

1. Do we need full wraps for every vehicle?

Not always. Smaller vehicles may use partial wraps if the design maintains brand consistency. Larger vehicles benefit from full wraps for maximum visibility.

2. How often should we rewrap our fleet?

Most fleets rewrap every 5–7 years, depending on factors such as sun exposure, maintenance, and the quality of the material.

3. What if part of our fleet is leased?

Use removable or partial graphics on leased units. Keep full wraps for owned vehicles.

4. What if our fleet is inconsistent today?

Start with a pilot redesign + phased rollout. Correct the most visible vehicles first.

5. How do we manage consistency across multiple states?

Use a central brand hub, master color swatches, approved vendors, and QC audits.

6. Can we run promotions without rewrapping vehicles?

Yes. Use seasonal overlays on approved zones without disrupting the base wrap.

7. How do we choose the right vendor?

Select vendors with certified installers, spectrophotometer color matching capabilities, and experience with fleet rollouts.

8. What’s a realistic budget for 20–50 vehicles?

Budgets vary by vehicle type and wrap coverage, but most fleets fall between $80k–$180k.

9. How long does a full fleet rollout take?

A typical 50-vehicle multi-site rollout takes 12–20 weeks, depending on regions and scheduling.

10. How do we measure branding effectiveness?

Track visibility, inbound calls, online searches, and customer recall in target regions.

11. What happens if our brand updates mid-cycle?

Use a “phase-in” strategy: update the oldest wraps first or rebrand during scheduled replacements.

12. Can we update the fleet gradually over several years?

Yes. Many companies transition in 3–4 phases, keeping older vehicles on-brand with partial updates.

Conclusion

A consistent fleet doesn’t happen by accident. It requires:

- Clear brand guidelines

- Strict color and material standards

- Scalable vehicle design systems

- Structured multi-site rollout workflows

- Strong QC and maintenance processes

- Continuous fleet tracking + governance

Companies that follow these systems enjoy:

- Stronger brand recall

- Higher customer trust

- Lower long-term costs

- Faster deployment across multiple regions

If you want BlinkSigns to audit your fleet or build a complete brand system:

?| Request a Fleet Branding Consistency Audit

?| Send your fleet photos for a free evaluation