Security Film Standards: Testing & Certification Explained

When architects, facility managers, or procurement officers evaluate security window films, they often encounter a maze of unfamiliar codes—ANSI Z97.1, CPSC 16 CFR 1201, UL 972, ASTM E1886, and Miami-Dade NOA. Each represents a distinct testing protocol, yet many decision-makers treat them as interchangeable. That misunderstanding can lead to expensive specification errors, rejected permits, or even safety failures after installation.

Every certified film on a BlinkSigns project carries a verified test report from accredited laboratories such as UL, Intertek, or NGS Testing Services. These certifications prove a product can withstand real-world impact, pressure, and blast scenarios—not just theoretical marketing claims. This article explains how standards work, their existence, and what specifiers must verify before approving a product.

Why Security Film Standards and Certifications Matter

Building Code Compliance Requirements

Modern building codes treat glass as a structural element subject to strict safety criteria. The International Building Code (IBC 2406) in the United States references ANSI Z97.1 and CPSC 16 CFR 1201 as mandatory for glazing in doors, sidelites, and other “hazardous locations.” Local inspectors require proof that any applied film maintains or exceeds the certified safety level.

Even a high-quality film may fail inspection without documentation because the glazing assembly no longer matches its certified configuration. BlinkSigns ensures that installations meet specifications by utilizing only products that have been tested in the circumstances in which they will be used, such as the type of glass, its thickness, and how it is attached.

Insurance and Liability Protection

For insurers, certifications are not academic; they are actuarial. Certified films demonstrate reduced risk of break-in losses, storm damage, and personal injury, often translating to lower premiums or deductible credits. In contrast, uncertified or mis-specified films can void coverage after an incident.

A documented test report provides defensible evidence in liability cases, proving the building owner used materials that meet recognized safety-glazing standards. BlinkSigns maintains archived certification data for every system installed, allowing clients to supply immediate proof of compliance when underwriter or claims requests arise.

Government and Institutional Requirements

Federal and state agencies impose safety glazing rules extending beyond the IBC. The General Services Administration (GSA), Department of Defense (DoD), and Department of Education each reference unique testing standards, such as GSA TS01 for blast mitigation or ASTM F1642 for air-blast performance.

Hospitals and healthcare facilities governed by NFPA 101 Life Safety Code also rely on certified glazing to prevent injury during emergencies. In these regulated environments, “equivalent performance” claims are insufficient—only documented compliance satisfies procurement auditors. BlinkSigns coordinates directly with testing bodies to confirm every specification aligns with applicable government standards before installation begins.

Performance Verification and Transparency

Certification is not simply a stamp—it’s a measurable demonstration of impact energy absorption, fragment retention, and adhesion integrity. Testing confirms how glass behaves under stress, how fragments adhere to the film, and whether the bonded system stays in its frame during wind or blast loading.

Independent verification prevents over-promising and allows clients to compare data transparently. BlinkSigns interprets these test results in plain language, explaining what each rating—Class A, Category II, or Minimal Hazard—means in practical protection levels. This clarity helps decision-makers budget accurately and choose film systems suited to their threat profile instead of relying on generic product claims.

How Security Films Are Tested

How Security Films Are Tested

Every primary standard measures one or more physical threats: human impact, forced entry, hurricane debris, or blast pressure. Even though test setups can differ, they all have three things in common: controlled impact energy, consistent measurement, and clear pass/fail rules based on keeping fragments.

- Impact Resistance Testing – Standards such as ANSI Z97.1, CPSC 16 CFR 1201, and EN 12600 simulate accidental human impact. A 100-pound soft-body impactor or 50-kilogram pendulum strikes the glass, and evaluators record whether the film prevents dangerous shards from detaching.

- Forced Entry Resistance – UL 972 and EN 356 replicate burglary attempts using repeated steel ball or axe impacts. The objective is not to make glass unbreakable but to delay penetration long enough for alarms or security response—typically 3 to 5 minutes in UL testing.

- Hurricane and Wind Load Resistance – ASTM E1886/E1996 and Miami-Dade TAS 201/203 simulate high-velocity debris strikes followed by thousands of pressure cycles (up to 9,000) representing sustained hurricane winds. Pass/fail depends on how the film bonds glass fragments while maintaining frame attachment.

- Blast Mitigation Testing – Federal standards such as GSA TS01 and ASTM F1642 measure how glazing responds to sudden overpressure from explosions. Testing uses a shock tube that generates blasts between 4 and 7 psi at defined impulse durations (28–42 psi·msec). Success means the glass may crack but remains captured by the film and attachment system, minimizing hazards to occupants.

Accredited laboratories verify film performance and complete system integrity throughout these processes—including glass type, thickness, and edge anchoring. Slight deviations in installation method can change results dramatically, so BlinkSigns treats laboratory data as design specifications, not marketing collateral.

Transition

Understanding the overall testing framework lays the groundwork for examining the specific standards that govern each performance category. The following section details the American safety and security glazing standards—ANSI Z97.1, CPSC 16 CFR 1201, and UL 972—and explains how their results define the baseline for compliance across most U.S. commercial and institutional projects.

American Safety & Security Standards

How Security Films Are Tested

ANSI Z97.1 – Safety Glazing Materials Used in Buildings

What It Is:

The American National Standards Institute (ANSI) established Z97.1 as the foundational test for building safety glazing materials. Its purpose is straightforward: to prevent cutting or piercing injuries when glass breaks. The standard defines how glass and applied films behave under human impact, ensuring fragments remain bonded rather than scattering dangerously.

How It’s Tested:

Laboratories use a 100-pound soft-body impactor—often a leather bag filled with lead shot—dropped from a specific height onto the glass.

- Class A: 48-inch drop height (≈ 400 ft-lb impact energy)

- Class B: 18-inch drop height (≈ 150 ft-lb impact energy)

A glazing passes when it resists penetration and retains fragments in a recognizable pattern.

Where It Applies:

The International Building Code (IBC 2406) mandates ANSI Z97.1 compliance for doors, sidelites, shower enclosures, and any glazed area adjacent to walking surfaces. Many local codes also adopt it for office partitions and storefront windows.

Certification & Marking:

Compliant products display an etched or printed mark showing “ANSI Z97.1–[Year].” Inspectors rely on this to verify safety glazing compliance during occupancy review. BlinkSigns only uses and installs films that have been tested to meet ANSI Z97.1 Class A for all commercial and institutional projects that need safety glazing performance.

CPSC 16 CFR 1201 – Federal Architectural Glazing Standard

What It Is:

Issued by the Consumer Product Safety Commission (CPSC), 16 CFR 1201 elevates ANSI Z97.1 into a federally enforceable regulation. It defines impact-resistance requirements for “architectural glazing materials” in residential and public buildings. While the test method mirrors ANSI’s procedure, CPSC certification carries legal authority for consumer protection and product recall enforcement.

Testing Categories:

- Category I: 18-inch drop (≈150 ft-lb) – low-risk zones

- Category II: 48-inch drop (≈400 ft-lb) – high-risk or high-traffic zones

Both require the same soft-body impact apparatus, fragment retention evaluation, and penetration resistance criteria.

ANSI vs CPSC – Key Difference:

Functionally, the testing setup and energy levels are nearly identical. The distinction lies in regulatory weight: ANSI is a voluntary consensus standard, while CPSC enforces compliance for consumer-facing architectural products under federal law.

BlinkSigns Application:

All BlinkSigns’ security films rated for safety applications hold dual compliance—ANSI Z97.1 Class A / CPSC Category II—ensuring readiness for any nationwide commercial or institutional code requirement.

UL 972 – Burglary-Resisting Glazing Material

What It Is:

The Underwriters Laboratories (UL) created UL 972 to measure resistance to forced-entry attacks. Unlike ANSI or CPSC, which focus on human impact safety, UL 972 evaluates a glazing system’s ability to delay penetration during break-ins or vandalism events.

How It’s Tested:

A steel ball weighing 8.18 pounds is dropped five times from 12 feet onto the glass. The sample must withstand all five impacts without allowing the ball to pass through. Some laboratories extend the test with hammer and chisel strikes to simulate burglary attempts.

Performance Meaning:

Passing UL 972 certification indicates a 3–5 minute forced-entry delay, enough time for alarm activation and response—critical in retail, banking, and high-value commercial environments.

Insurance Recognition:

Many insurance companies give discounts on policies for storefronts that have UL-listed glazing. The standard’s recognition extends across North America, including ULC Canada certification for cross-border projects.

BlinkSigns Application:

BlinkSigns specifies 8–12 mil films for UL 972 performance, paired with impact protection attachment systems that bond film to frame. These assemblies meet insurer documentation requirements and deliver measurable burglary resistance for retail, hospitality, and commercial clients.

Hurricane & Windborne Debris Standards

ASTM E1886 / ASTM E1996 – Windborne Debris & Pressure Cycling

What They Are:

The American Society for Testing and Materials (ASTM) developed E1886 (test method) and E1996 (performance specification) to simulate hurricane debris impact and cyclic wind pressure. These standards check if glass systems can stay whole after being hit by objects carried by the wind and after being pushed and pulled for a long time.

How It Works:

- Impact Test:

- Small Missile: 2-gram steel balls fired at 130 ft/s

- Large Missile: 9-pound 2×4 lumber fired at 50 ft/s

The film must prevent penetration even if the glass cracks.

- Small Missile: 2-gram steel balls fired at 130 ft/s

- Pressure Cycling:

After impact, samples endure 9,000 positive and negative pressure cycles, replicating Category 5 hurricane conditions.

- Performance Rating:

Systems are assigned design pressures (±60, ±100, ±150 psf). Higher ratings indicate stronger resistance that is suitable for coastal high-rise applications.

BlinkSigns Application:

BlinkSigns installs 8–14 mil hurricane-rated films tested to ASTM E1886/E1996, complete with silicone edge sealing or impact protection attachments. These assemblies help protect storefronts, hotels, and public buildings from flying debris while maintaining visibility and energy efficiency.

Miami-Dade County NOA – High-Velocity Hurricane Zone Approval

What It Is:

The Miami-Dade County Product Control Division issues the Notice of Acceptance (NOA)—the nation’s strictest hurricane certification. Required in Florida’s High-Velocity Hurricane Zone (HVHZ), it confirms that a film system has successfully undergone tests for debris impact and pressure changes according to TAS 201, 202, and 203

Testing Parameters:

- TAS 201 – Impact Test: Two 9-lb 2x4s at 50 ft/s

- TAS 203 – Cyclic Pressure Test: 9,000 alternating pressure cycles

- Design Pressures: Up to 150 psf

A glazing system may crack but must retain fragments and stay anchored to its frame throughout the test.

Approval Requirements:

Manufacturers must submit results from approved laboratories (such as Intertek or UL) for NOA review. Installation instructions, edge sealants, and frame attachment details are part of the certification—meaning only approved installation methods maintain compliance.

BlinkSigns Application:

BlinkSigns provides Miami-Dade NOA–approved 12–15 mil film systems, featuring tested silicone attachment assemblies. These solutions are trusted in coastal regions and recognized nationwide as the gold standard for hurricane safety glazing.

Blast Mitigation & Government Testing Standards

GSA TS01 – Federal Blast Hazard Rating

What It Is:

The General Services Administration (GSA) developed TS01 to evaluate glazing performance under blast loading in federal facilities. It classifies hazard levels based on the distance fragments travel after an explosion simulation.

Hazard Levels:

- No Hazard: Glass remains in frame; no fragment projection.

- Minimal Hazard (Level 2): Small particles within 3 ft.

- Low Hazard (Level 3): Fragments reach 10 ft; minor injuries possible.

Typical test parameters: 4–7 psi peak pressure, 28–42 psi·msec impulse.

BlinkSigns Application:

BlinkSigns installs 8–15 mil blast-rated film systems, achieving Minimal to No Hazard ratings under GSA TS01. Every installation uses strong silicone to hold the film in place, making sure it stays secure during strong forces, which is necessary for federal, defense, and

ASTM F1642 – Airblast Loading Test

What It Is:

ASTM F1642 complements GSA TS01, specifying test procedures for glazing exposed to controlled air-blast waves. It uses a shock-tube apparatus or open-field detonation to measure pressure and impulse tolerance.

Performance Levels:

- No Hazard

- Minimal Hazard

- Very Low Hazard

- Low Hazard

- High Hazard (failure)

To pass, glazing must prevent fragment projection beyond defined safe distances.

BlinkSigns Application:

All BlinkSigns blast-mitigation systems are tested to ASTM F1642 Minimal Hazard performance, ensuring safety in embassies, courthouses, and critical infrastructure buildings.

Transition

By this stage, the American, hurricane, and blast standards define how films protect against real threats—from accidental impacts to catastrophic explosions. However, global construction increasingly demands international compliance, especially for multinational corporations and overseas projects.

The following section explores European and international standards—including EN 12600, EN 356, and ISO 16933—to clarify how these align with U.S. testing systems and what specifiers should require for worldwide project consistency.

European & International Standards

EN 12600 – European Pendulum Impact Test

What It Is:

The European Committee for Standardization (CEN) developed EN 12600, now the universal European safety-glazing benchmark that replaced Britain’s BS 6206. It evaluates how flat glass and applied films perform when impacted by a moving mass, using a 50 kg twin-tire pendulum to simulate a person striking glass.

Test Heights & Classifications:

- Class 1B1: 1200 mm drop – highest protection

- Class 2B2: 450 mm drop – moderate protection

- Class 3B3 190 mm drop – basic protection

Each sample is examined for breakage mode (Type A disintegration, Type B retention, or Type C cracking). Films achieving 1B1 classification provide fragment retention comparable to ANSI Z97.1 Class A.

BlinkSigns Application:

Security films installed for European or Middle-Eastern projects are independently tested to EN 12600 1B1 or 2B2, ensuring compliance with CE-marking requirements and international project tenders.

EN 356 – Manual-Attack Resistance

What It Is:

EN 356 measures how long glazing resists deliberate forced entry using repeated impacts from an axe or heavy steel ball. It complements EN 12600 by focusing on security, not just safety.

Key Ratings:

- P1A – P5A: Axe impacts (security level)

- P6B – P8B: Ball-drop sequence (anti-burglary)

A higher class means more strikes are required to open a 400 × 400 mm hole through the glass.

BlinkSigns Application:

Thicker 12–14 mil films with structural attachment systems have demonstrated P2A performance in European tests—ideal for storefronts, banks, and government facilities seeking non-intrusive burglary protection.

ISO 16933 – Explosion-Resistant Glazing

What It Is:

This International Organization for Standardization (ISO) protocol subjects glass assemblies to arena blast testing using actual explosives. Scenarios simulate vehicle bombs (100 – 500 kg TNT) and satchel charges (1 – 10 kg TNT) at varying stand-off distances.

Ratings:

Performance levels are expressed as ER (Class) designations (e.g., ER 30 C = 30 kg TNT equivalent, Class C hazard).

BlinkSigns Application:

ISO-tested films are used for global corporate and diplomatic projects requiring verified explosion-resistant glazing, complementing U.S. GSA/ASTM F1642 certifications.

Other Global Standards

- BS 6206 – Legacy British impact standard (Classes A/B/C)

- AS/NZS 2208 – Australia/New Zealand safety-glazing

- JIS A5759 – Japanese industrial standard for films

- GB 9962-88 – China’s national glazing standard

- DIN 52290 / 52337 – German impact and fragmentation tests

BlinkSigns Advantage: With a global certification network, BlinkSigns supports cross-border projects meeting regional standards without requiring multiple product substitutions.

Clarifying ASTM F3561-22 – The Common Specification Error

Clarifying ASTM F3561-22

What It Is:

The ASTM F3561-22 test was introduced to measure forced-entry and ballistic-resistance of complete glazing systems, including frames, not stand-alone films. It’s designed for active-shooter or riot-level security glass assemblies.

Why It’s Misused:

Many specifiers mistakenly list ASTM F3561-22 when they actually need retrofit film solutions. The standard’s scope excludes simple film-on-glass installations because it requires permanent framing systems capable of withstanding ballistic impact and heavy blunt-force assault.

When It Applies:

- New construction with integrated ballistic-resistant frames

- Secure facilities (police stations, courthouses)

- Projects combining laminated glass with embedded polycarbonate layers

Correct Standards for Retrofit Films:

- UL 972 – burglary resistance

- ASTM F1642 / GSA TS01 – blast mitigation

- EN 356 – manual-attack resistance

- ANSI Z97.1 / CPSC 1201 – safety glazing

BlinkSigns Advisory:

BlinkSigns actively helps architects and school districts avoid F3561-22 misapplications, saving clients from costly redesigns or bid conflicts while ensuring realistic, code-compliant protection.

Reading & Verifying Test Reports

Essential Components

- Accredited Laboratory Identification – Must list ISO/IEC 17025 accreditation and facility number.

- Specimen Description – Includes film name, thickness, adhesive type, glass type, and attachment system.

- Test Standard & Version – e.g., “ANSI Z97.1-2015 Class A.”

- Environmental Conditions – Temperature, humidity, and glass orientation.

- Results Summary – Individual sample outcomes, fragment photos, and pass/fail statements.

- Limitations – Maximum panel size, glass type, and installation conditions.

Red Flags to Watch

- Missing lab accreditation or report number

- Undated or >10-year-old tests

- Ambiguous product description (“8 mil film,” no brand)

- Reports referencing different glass or attachment types

- Marketing claims (“blast-resistant”) without test documentation

BlinkSigns Verification Process: Every film we install has a traceable test report archived within our compliance database, which is cross-verified with manufacturer certifications and installation parameters.

How to Write Effective Film Specifications

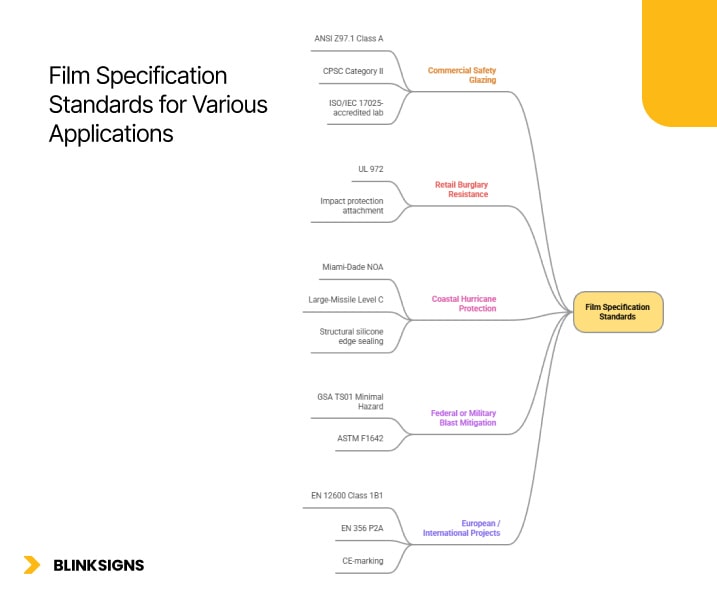

Film Specification Standards for Various Applications

Sample Specification Language

Commercial Safety Glazing:

Film shall be minimum four mil, tested and certified to ANSI Z97.1 Class A / CPSC Category II on ¼-inch annealed glass. Provide a test report from an ISO/IEC 17025-accredited lab dated within ten years.

Retail Burglary Resistance:

The film shall be 8–12 mil, UL 972 listed, and installed with a manufacturer-approved impact protection attachment, providing continuous edge retention.

Coastal Hurricane Protection:

Film shall be 12 mil minimum with Miami-Dade NOA for Large-Missile Level C, rated to ±150 psf. Install per NOA instructions using structural silicone edge sealing.

Federal or Military Blast Mitigation:

Film system shall achieve GSA TS01 Minimal Hazard at six psi / 42 psi·msec, tested with silicone-anchored edge retention. Provide an independent ASTM F1642 report.

European / International Projects:

Film shall be certified to EN 12600 Class 1B1 and EN 356 P2A. Provide CE-marking and current European test documentation.

These standardized clauses help architects, contractors, and facility owners write verifiable, code-compliant specifications.

Comprehensive Comparison Matrix

| Standard | Primary Purpose | Test Method | Impact / Load Level | Classification | Typical Film Thickness | Attachment Required? | International Recognition |

| ANSI Z97.1 | Human impact safety | 100 lb soft-body impactor (18 “/4 “drop) | 150 ft-lb (B) / 400 ft-lb (A) | Class A/B | 4–8 mil | Optional | U.S., Canada |

| CPSC 16 CFR 1201 | Federally regulated safety glazing | Same as ANSI Z97.1 | 150 ft-lb (I) / 400 ft-lb (II) | Category I/II | 4–8 mil | Optional | U.S. (federal) |

| UL 972 | Forced-entry resistance | 8.18 lb steel-ball drop (12 ft, 5 times) | Multiple impacts | Pass/Fail (no penetration) | 8–12 mil | Recommended | U.S., Canada |

| EN 12600 | Safety impact (pendulum) | 50 kg twin-tire pendulum | 190–1200 mm drop | 1B1–3B3 | 4–8 mil | Optional | Europe, the Middle East, and Asia |

| EN 356 | Manual-attack resistance | Axe / steel-ball impacts | 30–70 strikes are typical | P1A–P8B | 12–15 mil | Required | Europe, Global |

| GSA TS01 / ASTM F1642 | Blast mitigation | Shock-tube / air-blast test | 4–7 psi / 28–42 psi·msec | No – High Hazard | 8–15 mil | Required | U.S. Government, Global |

| Miami-Dade NOA (TAS 201/203) | Hurricane impact & pressure cycling | 9 lb 2×4 @ 50 ft/s + 9 000 cycles | ±60 – 150 psf | Pass/Fail (no penetration) | 12–15 mil | Required | U.S. (coastal), Global |

| ISO 16933 | Explosion-resistant glazing | Arena blast (1–500 kg TNT) | Variable standoff | ER Ratings (A–C) | 8–15 mil | Recommended | Global |

Frequently Asked Questions

What’s the difference between ANSI Z97.1 and CPSC 16 CFR 1201?

Both use identical impact tests, but CPSC enforces compliance federally. ANSI is voluntary; CPSC carries legal authority.

How thick should security film be for burglary resistance?

At least eight million to meet UL 972 performance; 12 million provides an extended delay when combined with an attachment system.

What is Miami-Dade NOA certification?

A product approval is required to verify that the film system passes TAS 201/203 hurricane impact and pressure-cycle tests, which are mandatory in Florida’s HVHZ zone.

Can a retrofit film meet ASTM F3561-22?

No. F3561-22 applies to complete framed glazing systems, not surface-applied films. Use UL 972 or ASTM F1642 for retrofit security performance.

How do I confirm a lab is accredited?

Check the report header for an ISO/IEC 17025 accreditation number or cross-verify through the lab’s accreditor database (A2LA, IAS, etc.).

Does a thicker film always mean better protection?

This is only possible when paired with a tested film-to-frame attachment and a matched glass type. Thickness alone doesn’t guarantee certification.

Are European EN 12600 and ANSI Z97.1 equivalent?

They measure similar human-impact energy; EN 1B1 ≈ ANSI Class A for specification purposes.

How long does certification testing take?

Depending on test scope and lab backlog, from 4 weeks (ANSI/CPSC) to 6–12 months (Miami-Dade NOA).

Do security films require re-certification?

Manufacturers renew certifications periodically or when formulations change; specifiers should request reports dated within the last 10 years.

Which standard should I specify for government buildings?

Use GSA TS01 Minimal Hazard or ASTM F1642 Low Hazard combined with ANSI Z97.1 Class A safety performance.

Conclusion

Understanding security film standards isn’t just about compliance—it’s about specifying performance confidently. Each code, test, and classification exists to ensure glazing systems protect people and property during real threats: accidental impact, intrusion, hurricanes, or explosions.

BlinkSigns bridges the gap between technical standards and field performance. Our certified installation teams use only films verified by ISO/IEC 17025-accredited labs and tested under the same configurations we install.

BlinkSigns consistently provides documentation, accuracy, and peace of mind, regardless of whether your project calls for ANSI safety compliance, UL burglary protection, or Miami-Dade hurricane certification. Contact us today