Vehicle Wrap Removal: Safe Techniques & Surface Restoration Tips

The moment wrap removal becomes “high stakes,”.

The wrap did its job. Perhaps it carried your branding for years, protected the paint, or helped you sell more. But removal is where things either go smoothly—or get expensive fast.

When removal is done correctly, vinyl lifts in controlled sections, and the finish underneath remains intact. When it goes wrong, you’re dealing with brittle film that tears into confetti, adhesive that smears into the clear coat texture, or clear coat lifting that can’t be “undone” with elbow grease.

Most online guides overlook the uncomfortable truth: vehicle wrap removal success depends heavily on what happened years earlier (installation quality), what occurred during the wrap’s life (UV, heat cycling, chemicals), and what you do in the first 10 minutes of removal (risk assessment and test peel).

This guide follows BlinkSigns’ Wrap Lifecycle Integrity Model, allowing you to choose the right path: a safe DIY approach when conditions permit, or a professional route when risk indicators are present.

The Wrap Lifecycle Integrity Model

Why removal difficulty begins 6+ years earlier—at installation

At BlinkSigns, we treat wraps as a managed lifecycle, not a one-time job. Installation quality, material choice, environment, and maintenance all shape what removal looks like years later. That’s the Wrap Lifecycle Integrity Model:

- Installation Quality → surface prep, material selection, technique

- Aging Behavior → UV, thermal cycling, edge integrity, adhesive curing

- Removal Difficulty → peel behavior, residue, paint preservation risk

- Surface Restoration → decontamination, correction, rewrap prep.

- Rewrap Performance → second-cycle adhesion, longevity, brand continuity

Key principle: each stage affects the next. A wrap installed over compromised paint or rushed preparation doesn’t just fail earlier—it often becomes harder to remove cleanly, and it can compromise the adhesion of the next wrap.

How installation quality determines removal ease

What professional installation does differently (and why it matters now)

Professional wrap installs reduce removal headaches later because they manage the things that “lock” vinyl into place:

- Surface energy management: proper decontamination and controlled and gentle wiping help the adhesive adhere correctly (neither too assertive nor too aggressive, allowing it to perform effectively without permanently adhering.

- Controlled heat and pressure during installation: the adhesive flows and sets predictably, rather than overheating into a paint-like texture.

- Knifeless tape where appropriate: fewer micro-cuts that can become failure points during removal.

- Correct post-heating and edge work: edges remain stable, reducing moisture intrusion and contamination creep.

- Correct film choice for vehicles: high-quality wrap films are engineered for removability within their service window (cheap “not-for-vehicle” films are not).

Reality check: a wrap can be the same age on two vehicles and still remove completely differently—because removal is essentially an installation-history problem disguised as a “removal technique” problem.

What happens to vinyl over 5–7 years

Over time, a wrap changes. The film loses pliability as the adhesive cures, and the vehicle’s environment amplifies both effects.

- UV exposure: film becomes brittle; adhesive hardens; tearing risk increases

- Heat cycling: adhesive “work-hardens” in stressed areas (curves, recesses)

- Moisture intrusion: edge lift lets contaminants under the film, complicating cleanup

- Chemical exposure: detergents, road salt, and fuel drips can alter adhesive behavior panel-by-panel

Practical takeaway: Most professional wrap films are easiest to remove within a defined service window. Once a wrap is far beyond that window, you’re more likely to see brittle tearing and heavier residue—especially around curves and edges.

Understanding your Removal Scenario

The three removal scenarios (and which one you’re facing)

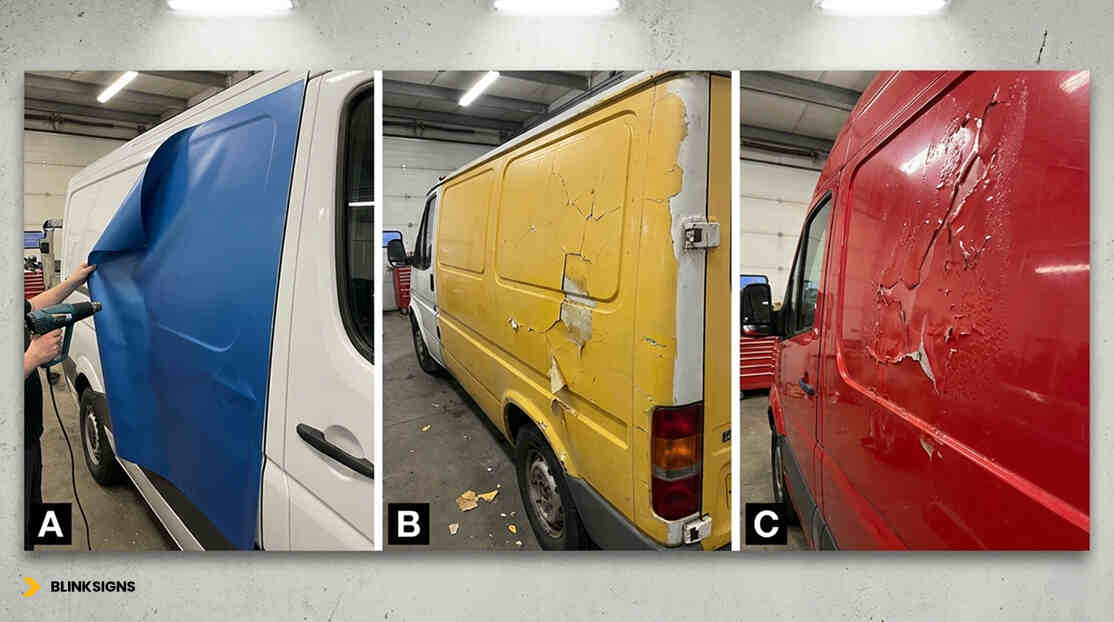

Wrap Removal quality tells everything

Scenario A: Ideal conditions (professional install, within service window)

Signs: clean edges, minimal cracking, consistent color, test peel lifts cleanly.

What removal looks like: larger sections come off with controlled heat and steady peel.

DIY viability: typically reasonable if you have the right tools and patience.

Scenario B: Aged or degraded wrap (brittle, fading, unknown install quality)

Signs: cracking, chalky look, brittleness, test peel tears easily.

What removal looks like: smaller pieces, heavy residue, frequent stopping/reheating.

DIY viability: possible, but risk rises quickly, professional removal is often the safer “cheaper” outcome once time + risk are factored.

Scenario C: Failed/damaged wrap (delamination, bubbling, wrong film, install defects)

Signs: wide peeling, bubbling, film splitting, confetti tearing, even with heat.

What removal looks like: unpredictable behavior across panels, high chance of paint/clear coat issues.

DIY viability: generally not recommended.

Pre-removal risk assessment (do this BEFORE you peel anything)

Most DIY failures start with skipping a 5-minute inspection.

Paint health checklist

Check these risk factors first:

- ☐ Repainted vehicle? Aftermarket paint varies; the risk of lift during removal increases.

- ☐ Existing apparent coat failure? Peeling/flaking, spider cracks, persistent haze = critical risk.

- ☐ Rust bubbles/stone chips/body filler edges? Wrap may be masking damage.

- ☐ Edge lift with contamination underneath? Dirt/water stains/corrosion near edges = more laborious cleanup.

- ☐ Was the wrap applied to fresh paint? Fresh paint can outgas and create adhesion/removal issues; some manufacturer guidance advises avoiding wrapping freshly painted vehicles and ensuring sufficient cure time.

Quick read:

- ✅ 0–1 risk factors → DIY can be reasonable with guardrails

- ⚠️ 2–3 risk factors → get a professional assessment before committing

- 🛑 4+ or “critical” clear coat failure → professional removal is the safer path

To make this assessment repeatable and mistake-proof, we use a structured removal checklist and planning worksheet. Download Here↴

Stop-now triggers (abandon DIY immediately if you see these)

If you see any of the following during removal, stop:

- 🛑 Clear coat lifts with vinyl

- 🛑 Paint color transfers to vinyl/adhesive

- 🛑 Adhesive turns gummy and smears into paint texture

- 🛑 Vinyl shatters into brittle confetti immediately upon heating

- 🛑 Clear coat shows hazing/clouding/color change after heating

These aren’t “hard mode.” They’re warning lights that indicate continuing can lead to increased repair work.

DIY vs Pro Removal: the 60-second decision tool

Choose DIY only if all are true:

- Scenario A conditions

- 0–1 paint risk factors

- Test peel releases cleanly

- Proper tools (heat + IR thermometer + plastic tools + safe removers)

- Enough time (no pressure to finish same day)

Choose Professional removal if any are true:

- Scenario B or C

- 2+ paint risk factors

- Test peel tears / heavy residue / any lift

- Fleet downtime matters

- Lease return consequences

- High-value vehicle or resale priority

- Immediate rewrap planned (surface prep has to be perfect)

DIY Removal — Step-by-Step Process

Tools and materials you’ll actually use

Essentials

- Heat source (a heat gun or steamer is standard)

- Infrared thermometer (don’t guess surface temp)

- Plastic razor blades / plastic scrapers (no metal edges)

- Plastic squeegee

- A lot of clean microfiber towels

Adhesive cleanup

- Automotive-safe adhesive remover

- Isopropyl alcohol (final wipe/residue check)

- Mild soap + water for final wash-down

Optional (big time-savers)

- Eraser wheel (used correctly, low speed, flat contact)

- Hair dryer for small/delicate areas

Manufacturer-aligned guardrail: Some wrap film guidance recommends using heat for removal and working at a slow, steady pace, at an angle not greater than 90°.

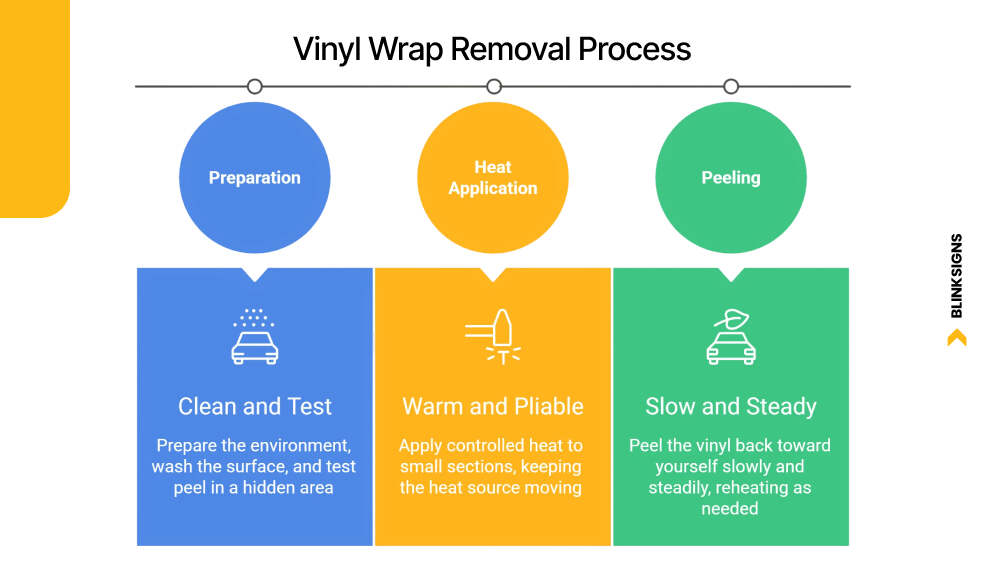

Vinyl Wrap Removal Process

Phase 1 — Preparation and environment

- Pick the right environment.

A controlled indoor space helps because vinyl and adhesive behavior can become unpredictable in extreme conditions. - Wash thoroughly

Focus on edges, trim, and recessed areas. Dirt becomes sandpaper when you’re dragging vinyl across paint. - Do a test peel in a hidden area.

Heat a small square, lift it gently with a plastic tool, and peel it with a controlled back-to-you motion.

- ✅ Good: clean release, minimal residue

- ⚠️ Caution: heavy stretch or resistance (you’ll need more heat control + smaller sections)

- 🛑 Stop: tearing immediately, clear coat lift, extreme residue

Phase 2 — Controlled heat application (the “don’t get cocky” part)

Your goal is warm and pliable, not hot and aggressive. Many film manufacturers describe removal using controlled heat within a moderate range (commonly around the 50–60°C / 122–140°F neighborhood for certain films).

Rules that prevent damage

- Keep the heat source moving (no hot spots)

- Work small sections (smaller on curves)

- Let temperature and peel response guide you—not speed.

Phase 3 — Strategic peeling technique

Peel direction: pull back toward yourself rather than pushing away—safer if the film tears and helps control force

Pace: slow and steady beats strong and fast (fast peeling increases the risk of tearing and delamination).

If resistance increases: stop, reheat, and continue. Forcing cold vinyl is how DIY turns into a multi-day cleanup.

Bringing Paint Back to Rewrap-Ready or Showroom Condition

Prep determines wrap lifespan

Removal is only one stage of the Wrap Lifecycle Integrity Model. The moment the vinyl is gone, the real question becomes: Is this surface healthy enough for the next wrap cycle, or does it need restoration first?

Most people judge the paint too early. They peel the wrap, see dullness or haze, and assume damage has happened. Often, what you’re seeing is contrast—wrapped paint that has stayed protected for years, while exposed areas have aged typically.

Why does paint look “off” after wrap removal (even when nothing is “wrong”)

- Protected vs. exposed panels: Wrapped areas were shielded from UV and oxidation. Unwrapped edges, bumpers, and lower panels weren’t.

- Micro-film residue: Even after adhesive removal, tiny polymers and contamination can sit inside the clear coat’s micro-texture.

- Light marring from removal work: Microfiber pressure, plastic tools, and residue cleanup can leave a faint haze that polishing easily corrects.

Phase 1 — Decontamination (the “rewrap-ready” foundation)

A rewrap fails when contamination stays behind. The surface may appear clean, but it can still be chemically incompatible for adhesion.

Decontamination sequence (panel-by-panel):

- Wash with pH-neutral automotive soap

- Dry thoroughly (especially around trim/edges)

- Clay bar with lubricant (straight lines, light pressure)

- Final wipe with isopropyl alcohol on clean microfiber (removes oils + leftover residue)

Quick surface test:

- Run a clean hand across the paint.

- If it feels “grabby” or gritty → you’re not ready yet.

Phase 2 — Correction (only as much as you truly need)

Paint correction isn’t always mandatory.

If you’re rewrapping soon:

- Aim for smooth + clean, not “perfect gloss.”

- A light polish is usually enough, unless there are visible defects that will telegraph through thin films.

If the vehicle will remain unwrapped (resale/appearance):

- Compound → polish → protection makes sense.

Phase 3 — Protection (only when you’re NOT rewrapping)

This is where many wraps fail in their second cycle.

If a rewrap is planned soon:

- Do not apply wax/sealant/ceramic before the new wrap.

- Those reduce surface energy and can cause edge lift and early failure.

If no rewrap is planned:

- Apply a protective layer after correction and final cleaning.

When DIY Fails — Rescue & Professional Intervention

DIY removal usually fails for one reason: people keep going when the surface is telling them to stop.

3M’s guidance for removal methods makes the core point clear: removal may be unaided, heat-aided, or chemically-aided, and the right approach depends on the film, substrate, and conditions—plus safety precautions for heat and chemicals.

Failure Point 1 — Vinyl tears into small pieces

Why it happens: brittle film, uneven heat, rushed pulling, wrong angle, aged wrap past its service window.

Rescue approach:

- Stop chasing significant sections. Accept smaller sections.

- Cut the film into manageable strips in cooler conditions to reduce stress during peeling (a technique referenced in 3M’s removal guidance).

- Heat evenly, keep the heat moving, and avoid hot spots that can burn surrounding paint.

When to stop DIY:

- Removal turns into “confetti” across multiple panels.

- Progress slows to inches per minute.

- You’re tempted to switch to metal blades or aggressive scraping.

Failure Point 2 — Adhesive residue won’t release

Why it happens: adhesive aging, environmental exposure, and film left longer than intended.

Rescue ladder (safe escalation):

- Warm the panel slightly (gentle heat)

- Mechanical roll-up with plastic squeegee

- Adhesive remover with correct dwell time + wipe technique

- Final isopropyl wipe to remove chemical residue.

3M specifically notes that chemical aids may be needed when heat alone won’t do it (especially after excessive environmental exposure or longer-than-intended time on the surface), and also emphasizes reading and following MSDS/safety guidance and testing chemicals in an inconspicuous area.

Failure Point 3 — Clear coat lifts/paint transfers (EMERGENCY STOP)

Stop immediately if you see:

- Clear coat lifting with vinyl

- color transfer

- Clouding/hazing that appears after heating and doesn’t wipe away

Continuing multiplies the repair scope. At that moment, the job is no longer “wrap removal.” It becomes paint preservation.

Failure Point 4 — Overheating damage

3M warns that higher-output heat sources can be less safe and may oxidize or burn surrounding painted areas, so controlling heat and maintaining constant movement are crucial.

Immediate response:

- Stop heating, let the area cool, and reassess the situation.

- Continue only if the surface shows no lasting change.

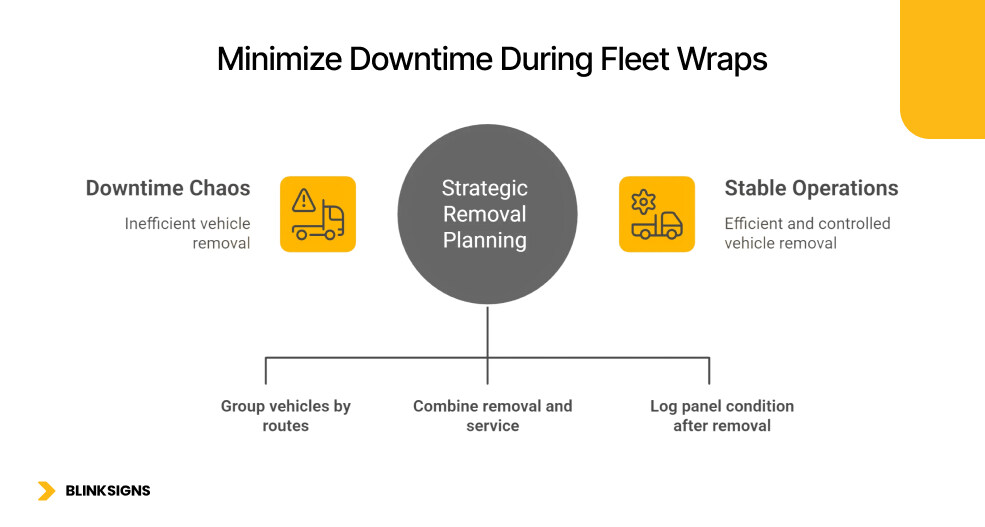

Fleet Wrap Refresh — Operational Planning

Fleet managers don’t lose money on removal itself. They lose money on downtime chaos.

Fleet removal scheduling that doesn’t disrupt operations

Batch by territory (not random vehicle order):

- Group vehicles by routes/service zones

- Stagger removals so coverage stays stable

- Build buffer capacity for surprise issues (aged panels, adhesive hotspots)

Pair removal with maintenance windows:

- Removal + scheduled service in the same downtime block

- Fix known panel issues before the rewrap day.

- One controlled interruption is better than multiple scattered interruptions.

Post-removal surface documentation (QC that protects the next wrap)

Create a simple panel log after removal:

| Panel | Adhesive residue level | Paint condition | Action needed before rewrap |

| Hood | Low | Good | Alcohol wipe + ready |

| Driver door | Medium | Light haze | Light polish + wipe |

| Rear quarter | High | Risk area | Deeper cleanup + inspect |

Minimize Downtime During Fleet Wraps

This is the Wrap Lifecycle Integrity Model in a real-life application: Stage 4 (restoration) determines Stage 5 (rewrap performance).

Special Cases & Advanced Scenarios

Leased vehicle returns (inspection-driven removal)

Lease returns punish small mistakes: residue in door jambs, edges under trim, and inconsistent gloss.

Pre-return checklist:

- All vinyl removed (including fuel door edges + jambs)

- No tackiness anywhere (hand test)

- No chemical staining on trim

- Clear coat intact (no delamination/clouding)

- Photo documentation of the final condition

Chrome, textured, and specialty films.

These behave differently due to their thickness, finish sensitivity, and adhesive characteristics.

Practical adjustments:

- Smaller working sections

- Slower peel

- More careful heat control

- Extra residue inspection on textured surfaces (adhesive hides in valleys)

Partial removal (decals, stripes, minor updates)

Partial removal fails when chemical overspray migrates under the remaining edge.

Precision method:

- Mask adjacent vinyl edges

- Apply remover with a controlled applicator (not a wide spray)

- Immediate edge wipe with a clean towel + alcohol

- Recheck edge adhesion after cleanup.

FAQ

1) Can a vehicle wrap be removed without damaging the paint?

Yes—when the paint is healthy, and the removal is done using controlled heat, safe tools, and the correct peel method. Paint damage usually occurs when the clear coat is already compromised or when removal is too aggressive.

2) Should the wrap be cut into strips before removal?

Sometimes. Cutting into manageable strips can make removal easier in cooler conditions and reduce stress during the peeling process.

3) When do chemicals become necessary?

When heat-aided removal fails to release the film or adhesive, often due to environmental exposure or the wrap remaining in place longer than intended, always test first and follow safety guidance.

4) What’s the biggest mistake people make during removal?

Forcing a cold or resistant section. Resistance is a signal to stop, reheat evenly, reassess the angle, or escalate methods safely.

5) What should I do after removal if I’m rewrapping soon?

Decontaminate, then perform only the necessary corrections for smoothness. Finish with an alcohol wipe—avoid using waxes or sealants before the next wrap.

Final Thought

If you’re planning a refresh cycle, the safest path is the one that protects your paint and ensures a strong bond for your next wrap. BlinkSigns can help you assess your removal scenario, document surface conditions after removal, and prep the vehicle for a clean second cycle using the Wrap Lifecycle Integrity Model.