Vehicle Wrap Materials Guide: Choosing the Right Vinyl for Performance & Durability

Why the Right Vinyl Material Matters

Vehicle wraps have become one of the most powerful ways for businesses to increase visibility, modernize their brand presence, and protect their vehicles, all at a fraction of the cost of a new paint job. But while design often gets the spotlight, vehicle wraps’ material selection is the genuine performance factor. The type of vinyl, finish, adhesive system, and durability rating you choose determines:

- How long does the wrap last?

- How well it holds up to UV, heat, chemicals, and road debris?

- Whether it keeps its color and shape?

- Whether it fails early (peeling, cracking, fading) or performs for 5–7 years?

- The total ROI your fleet or commercial wrap delivers?

The global vehicle wrap market has experienced rapid growth, driven by a surge in fleet branding, small business advertising, rideshare vehicles, and high-end customizations.

But as demand expands, so does the gap in understanding which materials perform best.

Some vinyl films are engineered for long-term use in commercial fleets, where trucks travel tens of thousands of miles annually.

Others are produced for short-term promotions, limited budgets, or personal use, where longevity expectations differ.

Choosing the wrong material can shorten lifespan by 40–65%, increase maintenance costs, and lead to peeling, shrinkage, or color fading within months.

BlinkSigns works with businesses across trucking, logistics, healthcare, food delivery, and corporate fleets — and in every project, the conversation starts with one question:

“Which vinyl film is right for your vehicle and environment?”

This guide walks you through the science, performance, and real-world durability of vehicle wrap materials, enabling you to make informed decisions for long-term results.

Types of Vinyl Wrap Films — Cast vs Calendared

Vinyl Wrap Films Cast vs Calendared

There are dozens of vinyl films on the market, but nearly all fall into two manufacturing categories: cast vinyl and calendared vinyl. Understanding how each is produced is crucial because the manufacturing process directly impacts durability, flexibility, and overall performance.

Cast Vinyl — The Premium, Long-Term Material

Cast vinyl begins as a liquid mixture poured onto a casting sheet and baked until it forms a thin film. This method produces a highly stable, flexible, and long-lasting vinyl.

Key Performance Traits of Cast Vinyl:

- Durability: 5–7 years (sometimes more with proper maintenance)

- Excellent conformability: Wraps deeply into curves, rivets, and channels

- Thin & flexible: ~2 mils thick, ideal for complex shapes

- Minimal shrinkage: Maintains shape long-term

- Best for: Commercial fleets, full wraps, long-term branding, high-heat environments

Premium Brands Used by Professional Installers

- 3M™ Wrap Film Series 2080

- Avery Dennison Supreme Wrapping Film

- Orafol ORAJET 3951 Cast Series

Cast films are the industry standard for professional-grade wraps and high-performance fleet branding.

Calendared Vinyl — Short-Term or Budget-Friendly Option

Calendared vinyl is made by rolling heated PVC through pressure rollers, much like dough is processed in a pasta machine. The process stretches the vinyl, making it thicker, less flexible, and more prone to shrinkage.

Key Traits of Calendared Vinyl:

- Durability: 1.5–3 years

- Moderate conformability: Good for flat surfaces only

- Thickness: 3–5 mils — harder to mold to curves

- Higher shrinkage risk over time

- Best for: Short-term promotions, temporary graphics, seasonal wraps

Typical Uses:

- Event-based branding

- Short-term retail promotions

- Budget-conscious personal wraps

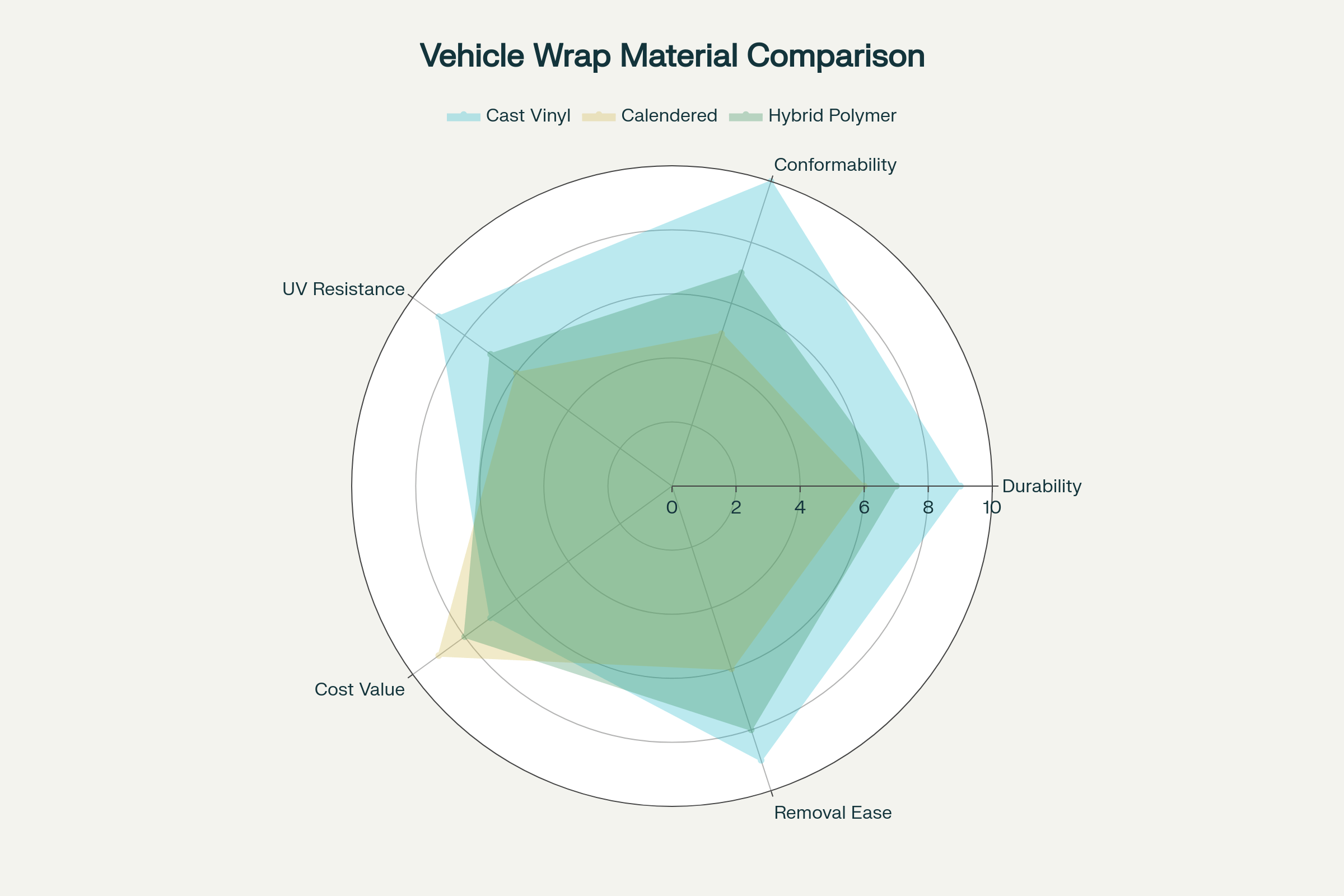

Cast vs Calendared — Quick Comparison

vehicle wrap material comparison

| Property | Cast Vinyl | Calendared Vinyl |

| Manufacturing | Liquid cast, baked | Rolled/extruded |

| Durability | ⭐⭐⭐⭐⭐ (5–7 yrs) | ⭐⭐ (1.5–3 yrs) |

| Shrinkage | Minimal | High |

| Flexibility | Excellent | Moderate (flat surfaces only) |

| Conformability | Best for curves, rivets | Best for flat areas |

| Ideal Use | Fleets, long-term wraps | Short-term graphics |

Most commercial fleets require cast vinyl unless a short-term campaign is intended. This early decision has a significant impact on cost, lifespan, and brand consistency.

Vinyl Finish & Aesthetic Options — More Than Just Style

Vinyl Finish & Aesthetic

Finishes aren’t just about looks — they influence durability, maintenance, temperature resistance, and even color fading. Below are the most common options, along with their performance implications.

Gloss Finish

Gloss wraps closely resemble automotive paint and reflect light well.

Pros:

- Vibrant color reproduction

- Smooth, polished look

- Easy to clean and maintain

Cons:

- Shows scratches more easily

- Requires UV protection in sunny climates

Matte Finish

Matte offers a soft, non-reflective look that has become a trend in both personal and commercial vehicles.

Pros:

- Modern, premium aesthetic

- Hides minor imperfections

Cons:

- Can catch dirt and oils faster

- Requires gentler washing techniques

Satin Finish

A balance between matte and gloss — soft reflection without high shine.

Best For: Corporate fleets seeking a modern look with better maintenance flexibility.

Chrome & Metallic Finishes

These produce dramatic, reflective effects but come with unique considerations.

Pros:

- Extremely eye-catching

- Ideal for luxury, sports, and marketing vehicles

Cons:

- Lower durability than cast matte/gloss

- Sensitive to heat and sunlight

- Higher cost

Textured Films (e.g., carbon fiber)

Popular for detailed work on hoods, roofs, and mirrors.

Pros: Durable, hides light scratches

Cons: Best used on small sections, not full wraps

How Finish Impacts Durability

- Gloss: Long-lasting with proper care

- Matte: Prone to staining if not maintained

- Chrome: Lowest durability; highest cost

- Satin: Best balance of maintenance + style

The finish choice should align with the environment, vehicle type, and brand requirements.

Durability & Environmental Performance — What Really Determines Wrap Lifespan

A vehicle wrap’s lifespan isn’t determined solely by the type of vinyl.

Environmental exposure, UV levels, installation quality, wash routines, and temperature swings all significantly impact long-term durability.

Here are the primary performance variables:

1. UV Exposure

Sunlight is the #1 cause of:

- Color fading

- Vinyl brittleness

- Adhesive weakening

Vehicles in southern climates (Texas, Arizona, Florida) experience accelerated degradation. Cast vinyl with UV protection resists fading far better.

2. Temperature & Weather Conditions

- Extreme heat causes vinyl to stretch or soften.

- Freezing temperatures make vinyl brittle.

- Road salt corrodes edges and seams.

- Rain and humidity impact adhesive longevity

Commercial vehicles often face all of these stressors on a daily basis.

3. Chemical Exposure

Common wrap-damaging chemicals include:

- Fuel vapors

- Harsh detergents

- Automated car wash brushes

- Degreasers

- Industrial cleaners

Fleet vehicles, such as food delivery vans or utility trucks, must use high-grade films designed for chemical resistance.

4. Surface Preparation & Installation Quality

No material — even the best cast vinyl — can perform well if misapplied.

Key steps include:

- Deep degreasing

- Removing wax or ceramic coatings

- Cleaning edges, cracks, and seams

- Using correct heat application

- Applying edge sealants

- Avoiding overstretching the film

Poor prep leads to early failure, bubbling, peeling, and shrinkage.

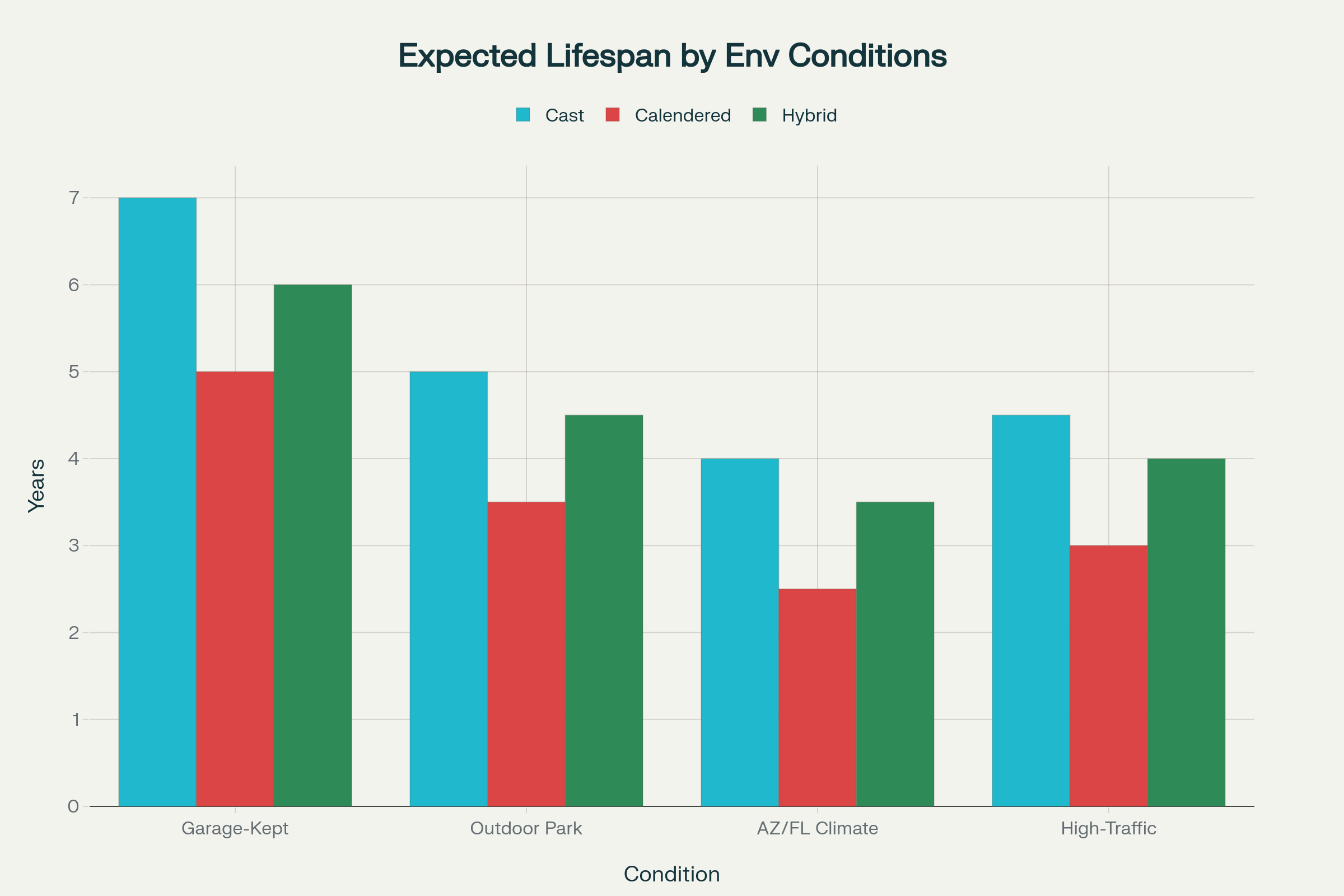

5. Expected Lifespan By Material Type

| Material | Typical Lifespan | Notes |

| Premium Cast Vinyl | 5–7 years | Best for fleets & full wraps |

| Mid-Grade Cast | 4–5 years | Good for small businesses |

| Calendared Vinyl | 1.5–3 years | Best for temporary graphics |

| Chrome/Metallic Films | 1–2 years | Lowest UV resistance |

| Textured/Carbon Fiber | 3–5 years | Used on accents only |

Vinyl lifespan expectations chart

The lifespan can vary by climate. A 7-year cast wrap in Ohio might last 4–5 years in Arizona under identical maintenance habits.

Installation Quality & Maintenance — Extending Vinyl Life

Even the most durable film will underperform if installed poorly or maintained incorrectly.

Installation of Vehicle vinyl wrap

Professional Installation Factors

- Correct squeegee pressure

- Heat gun calibration

- Post-heating around curves

- Proper trimming around recessed areas

- Avoiding overstretching

These details separate professional-grade performance from early failure.

Maintenance Essentials

- Wash with mild soap (never automatic brushes)

- Avoid high-pressure jets near edges.

- Remove bird droppings or tree sap immediately.

- Use wrap-safe cleaners

- Inspect edges every 3–4 months.

Removal

Quality cast vinyl removes cleanly with minimal adhesive residue.

Cheap calendared vinyl often cracks during removal, increasing labor costs.

Choosing the right vinyl can save you thousands in rewraps, downtime, and brand inconsistency — especially for fleet vehicles. BlinkSigns helps businesses select the ideal vinyl film for their specific climate, usage, and branding objectives. From premium cast wraps for long-term performance to specialized finishes for marketing campaigns, our experts guide you through every step — from material selection and design to printing and installation. ? Request a Free Vehicle Wrap Material Consultation https://blinksigns.com/contact-us/

Performance Metrics: How Vinyl Films Behave in Real Conditions

The actual test of a vehicle wrap is not how it looks on installation day — it’s how it performs after months of sun exposure, thousands of miles on the road, repeated washes, and changing weather conditions.

Material selection directly affects:

- Fade resistance

- Adhesive stability

- Edge integrity

- Conformability over curves

- Shrinkage and lifting

- Resistance to cracking and peeling

High-quality cast vinyl maintains color, flexibility, and bond strength even under heavy environmental stress. Calendared films, by comparison, tend to degrade faster because the extrusion process introduces internal stress to the material.

Cast Vinyl Performance — Benchmark for Fleet Durability

Premium cast films (3 M, Avery Dennison, Orafol) undergo a “relaxed” curing process, resulting in a material that remains dimensionally stable. This means:

- Edges stay sealed longer

- Colors stay vibrant even under intense UV exposure.

- Minimal shrinkage over the lifespan of the wrap

- No cracking when stretched around curves and channels

Cast vinyl also includes air-release and repositionable adhesive technologies, making installation cleaner and reducing the likelihood of bubbles or improper bonding.

Calendared Vinyl Performance — Adequate for Short-Term Use

Calendared vinyl performs well in:

- Short-term promotions

- Limited-area graphics

- Seasonal or temporary branding

However, it is not designed for long-term exposure. Typical performance issues after 18–24 months include:

- Shrinkage around edges

- Loss of adhesion in high-heat zones

- Rapid fade when exposed to intense sunlight

- Increased brittleness

This degradation affects both appearance and the total cost of ownership.

Brand-Level Performance Comparison (Generalized)

A performance model typically looks like:

| Brand / Material Class | Average Lifespan | Fade Resistance | Edge Stability | Fleet Suitability |

| 3M™ Cast Vinyl | 6–7 years | Excellent | Excellent | Ideal |

| Avery Dennison Supreme | 5–7 years | Excellent | Excellent | Ideal |

| Orafol Cast Series | 5–6 years | Excellent | Very Good | Ideal |

| Calendared Mid-Grade Film | 2–3 years | Moderate | Low | Limited |

| Budget Calendared Film | <2 years | Low | Low | Not Recommended |

For any business where vehicles operate daily and represent the brand publicly, cast vinyl remains the most cost-effective and durable option.

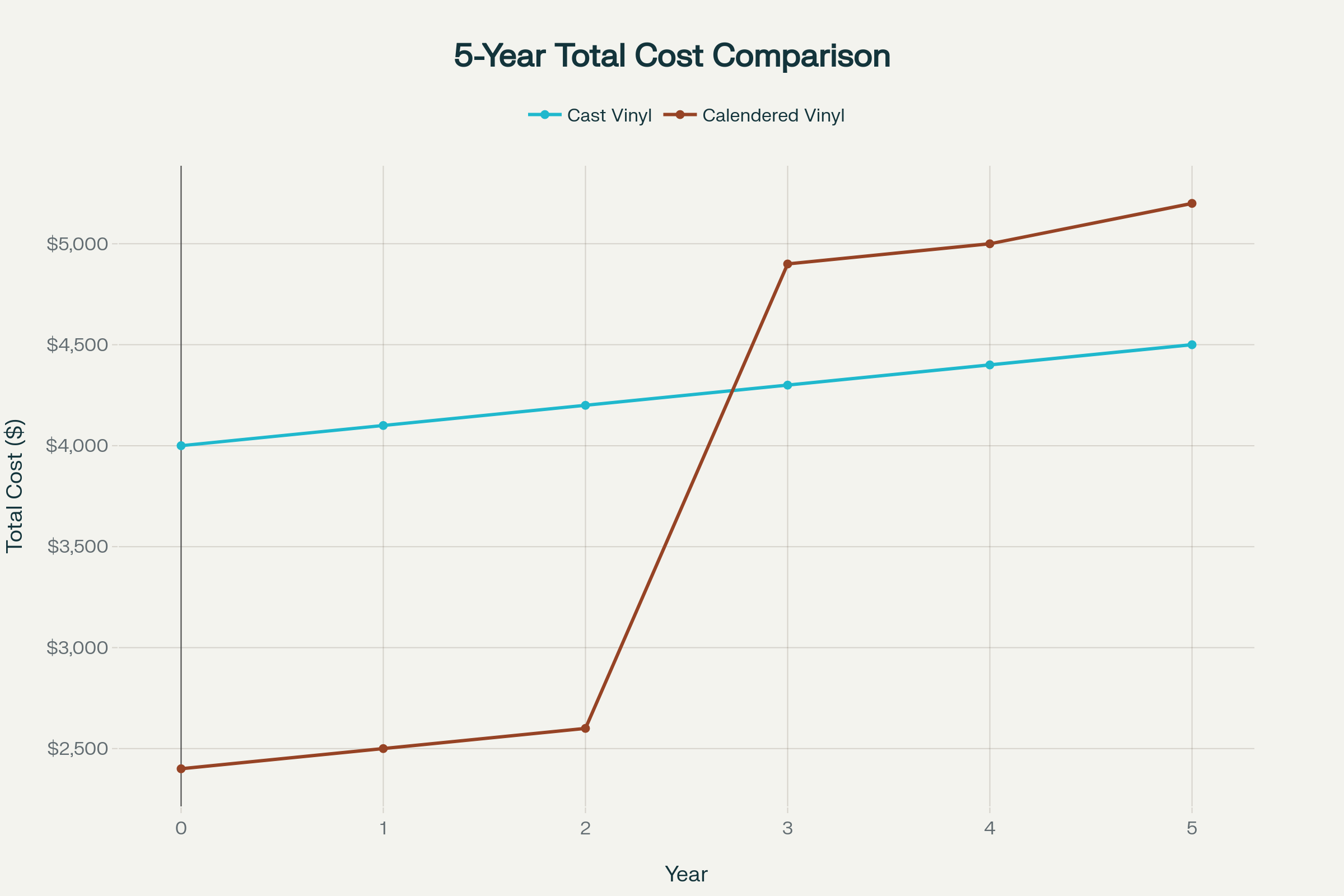

Cost vs. Lifespan Analysis — The Real ROI of Vinyl Wrap Materials

When choosing material, many buyers make the mistake of comparing only the upfront cost per square foot. But the actual cost difference comes from:

- Lifespan

- Frequency of replacement

- Maintenance requirements

- Labor for rewraps or repairs

- Downtime when vehicles are off the road

A premium cast wrap may cost more initially, but its additional 3–4 years of durability nearly always delivers a lower cost-per-year and higher ROI.

Example Cost Model (Generalized)

| Material Type | Installed Cost (avg) | Lifespan | Cost Per Year |

| Cast Vinyl | $3,500 | 6 years | $583/year |

| Calendared Vinyl | $2,200 | 2 years | $1,100/year |

Although calendared vinyl is cheaper upfront, the wrap must be replaced three times within the lifespan of a single cast wrap.

Vinyl Five-year cost analysis

Additional Value Factors for Cast Vinyl

- Reduced fading means branding stays consistent.

- Fewer repair calls for lifting edges or bubbles

- Higher resale value since the wrap protects the original paint

- Increased impressions for vehicles in high-traffic areas

A fleet van in a significant city generates 30,000–70,000 daily impressions, making wrap longevity crucial for achieving advertising ROI.

Fleet Use Cases: Matching Material Choices to Real-World Vehicle Demands

Different industries place unique demands on their vehicles, which should guide material selection.

Logistics & Delivery Fleets

These vehicles experience:

- Long hours in direct sunlight

- Frequent road debris impact

- Continuous high-speed airflow

- Multiple wash cycles weekly

Recommended: Premium cast vinyl with high UV resistance.

Reason: These vehicles represent the brand every day and need reliable long-term durability.

Service Vehicles (Plumbing, HVAC, Electrical)

Challenges include:

- Constant door opening/closing

- Hot engine compartments near vinyl edges

- Exposure to oils, grease, and chemicals

Recommended: Cast vinyl with strong adhesive systems + edge sealing.

Food & Beverage Fleets

These vehicles undergo:

- Sanitation sprays

- Moisture exposure

- Parked heat buildup during deliveries

Recommended: UV-stable cast vinyl with extra laminate protection.

Corporate Fleet Branding

For fleets that require consistent colors and brand integrity:

- Pantone matching required

- Matte or satin finishes for brand consistency

- Long-term durability is needed for corporate identity cycles.

Recommended: Cast vinyl with color-matched premium films.

Seasonal or Short-Term Campaign Vehicles

For temporary promotions that last under 18 months:

Recommended: Calendared vinyl or promotional films.

Fleet operations benefit enormously from selecting the right vinyl grade — especially for vehicles that operate 6–7 days a week.

Case Study — US Storage Centers Vehicle Wrap Project

Vehicle wraps for US Self Storage

BlinkSigns has delivered high-quality vehicle wraps for businesses across the Midwest, including the widely recognized US Storage Centers project.

This project involved branded vehicle graphics designed to enhance visibility, improve wayfinding, and reinforce the company’s identity across its service vehicles.

Project Overview

US Storage Centers required durable, eye-catching vehicle branding that would:

- Maintain consistent color accuracy across locations

- Withstand year-round outdoor exposure.

- Present a polished, professional corporate identity.

- Support their marketing and customer acquisition journey.

BlinkSigns delivered high-visibility vehicle graphics printed on premium cast vinyl, ensuring excellent longevity and resistance to UV, heat, and weather fluctuations.

Material Choice: Why Cast Vinyl Was Essential

For this project, cast vinyl was selected because:

- Vehicles operate daily in full sun

- Smooth curves and panel transitions benefit from high conformability.

- Long-term color stability was essential for brand consistency.

- Storage center fleets remain in service for an extended branding cycle.

The wrap maintained exceptional clarity and color saturation, even through:

- Continuous wash cycles

- Outdoor storage

- Seasonal freeze–thaw cycles

Outcome

Although specific metrics are proprietary, the visual and functional results were precise:

- Consistent branding across the entire fleet

- High-visibility vehicles that supported brand recognition

- Long-term durability with minimal maintenance

- Professional presentation aligned with corporate standards

The US Storage Centers project remains an excellent example of how the right vinyl material delivers measurable branding impact for commercial fleets.

For more details, visit the official case study —>

Maintenance & Wrap Removal — Protecting Your Investment

Even the best vinyl requires proper maintenance.

The way you wash, store, and care for your vehicle wrap can significantly add to its life or dramatically reduce it.

Maintenance Guidelines

Do:

- Hand wash with mild detergent

- Use microfiber cloths

- Clean spills or contaminants immediately

- Inspect edges quarterly

- Park in shade or covered areas when possible

Avoid:

- Automatic brush car washes

- High-pressure spray directly on edges

- Abrasive polishes

- Petroleum-based cleaners

Proper care slows UV degradation, reduces staining, and maintains strong adhesive bonds.

Wrap Removal

High-quality cast vinyl removes cleanly with controlled heat, leaving minimal residue and protecting the original paint.

Calendared vinyl, in contrast:

- Often cracks during removal

- Leaves a heavier adhesive residue

- Increases labor costs

For businesses with large fleets, ease of removal is a significant cost factor — another reason cast vinyl is often the superior long-term investment.

FAQ

Q1: What’s the difference between cast and calendared vinyl?

Cast vinyl is poured and baked, resulting in superior flexibility, durability, and UV resistance. Calendared vinyl is rolled and stretched, making it thicker and less flexible, and is suitable only for short-term promotions.

Q2: How long do vehicle wraps last?

Premium cast wraps last 5–7 years with proper care; calendared wraps last 1.5–3 years, depending on climate and usage.

Q3: Which vinyl wrap material is best for commercial fleets?

Cast vinyl is recommended for fleets due to its long lifespan, fade resistance, and superior conformability.

Q4: Does the wrap finish affect durability?

Yes. Gloss and satin finishes typically last longer; chrome and metallic films degrade faster due to thinner top layers.

Q5: How do I properly maintain a vehicle wrap?

Hand washing, avoiding high pressure on edges, using wrap-safe detergents, and keeping vehicles shaded prolong vinyl life.

Q6: Will a wrap damage my paint?

No. Professional-grade vinyl protects OEM paint from UV, scratches, and debris — provided removal is done correctly.

Q7: How much does a vehicle wrap cost?

A typical full wrap ranges from $2,200 to $4,000, depending on vehicle size, film type, and finish.

Maximize Your Wrap Performance with the Right Material

The vinyl you choose determines how your wrap performs, how long it lasts, and how consistently it represents your brand.

From UV resistance and conformability to installation quality and maintenance habits, every factor contributes to total ROI.

BlinkSigns works with businesses across industries to guide them toward the right material — whether they operate a fleet of service vans, a logistics company, food delivery vehicles, or corporate cars.

If you want a wrap that:

✔ Lasts 5–7 years

✔ Maintains color accuracy

✔ Performs across seasons

✔ Protects your paint

✔ Enhances your brand

…then let BlinkSigns help you choose the perfect vinyl film for your vehicle or fleet.