Climate-Resilient Signage: Engineering Solutions for Extreme Weather Performance

Why Climate-Resilient Signage Matters

Extreme weather isn’t coming—it’s here. From Category 5 hurricanes devastating coastal businesses to record-breaking heat waves buckling traditional signage across the Southwest, climate challenges have moved from occasional concerns to operational reality.

The damage extends beyond repair costs when your business sign fails during a storm. The U.S. saw $92.7B in weather- and climate-disaster losses in 2023 and $182.7B in 2024; signage damage is part of these commercial losses—so designing for resilience is a business necessity. Dark signs signal closure. Damaged structures suggest neglect. Failed visibility means lost revenue.

At BlinkSigns, we engineer signage as critical infrastructure, not decorative displays. Our climate-resilient signage solutions protect your brand investment through scientific design, advanced materials, and comprehensive engineering that anticipates—and overcomes—nature’s most challenging conditions.

Why Weather-Resistant Signage Is a Business Essential

Weather disasters regularly create tens to hundreds of billions in losses annually in the U.S.; resilient sign engineering reduces avoidable loss and downtime for commercial sites.

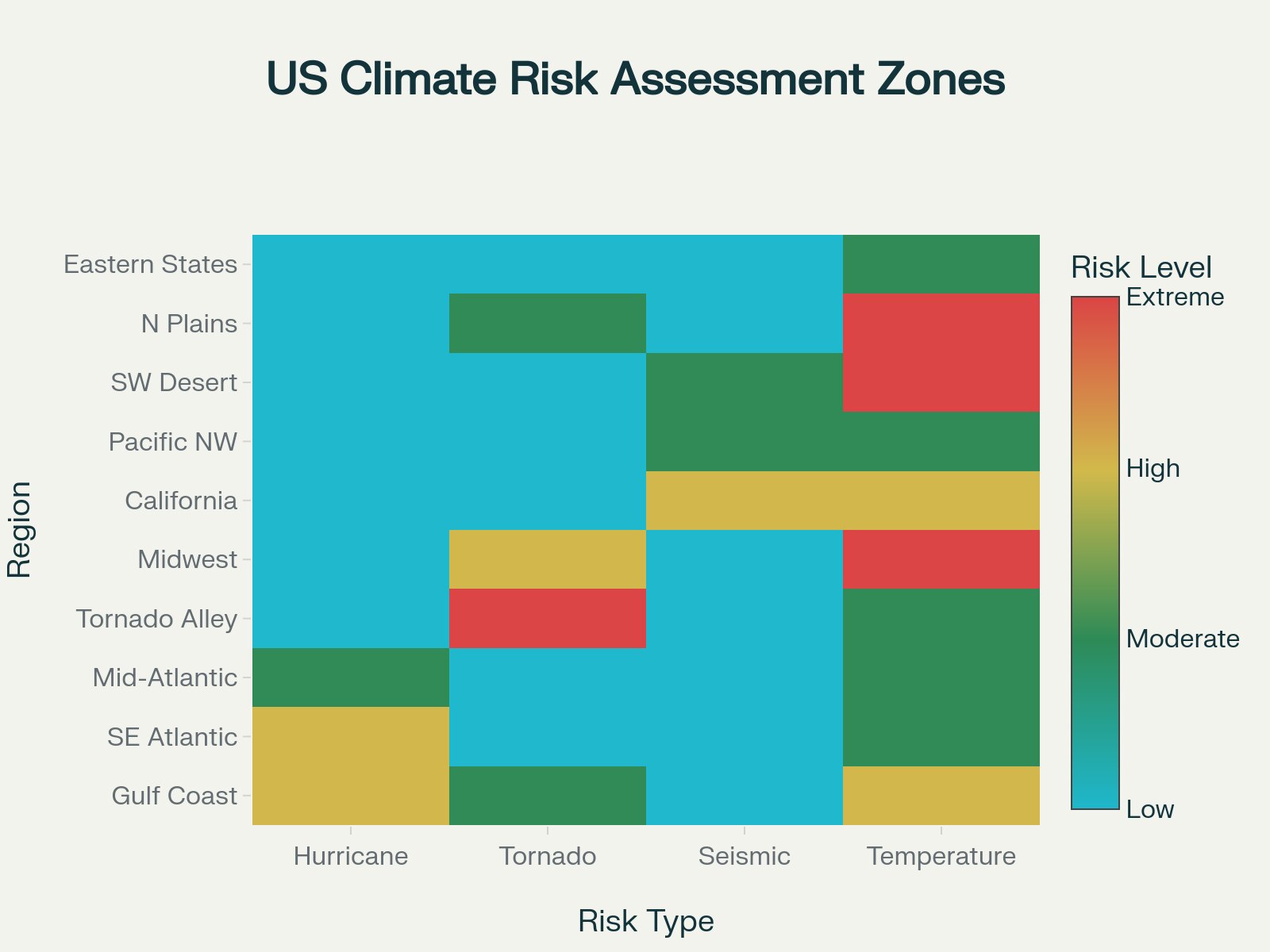

US Climate Risk Assessment Zones

The Hidden Costs of Climate Vulnerability

Immediate Impact:

- Emergency repair costs average 4x higher than planned maintenance

- Business interruption during critical recovery periods when foot traffic shifts

- Safety hazards create liability exposure and insurance complications

Long-Term Consequences:

- Brand perception damage from neglected appearance during recovery

- Customer uncertainty about business stability and operational reliability

- Competitive disadvantage, while properly prepared competitors maintain visibility

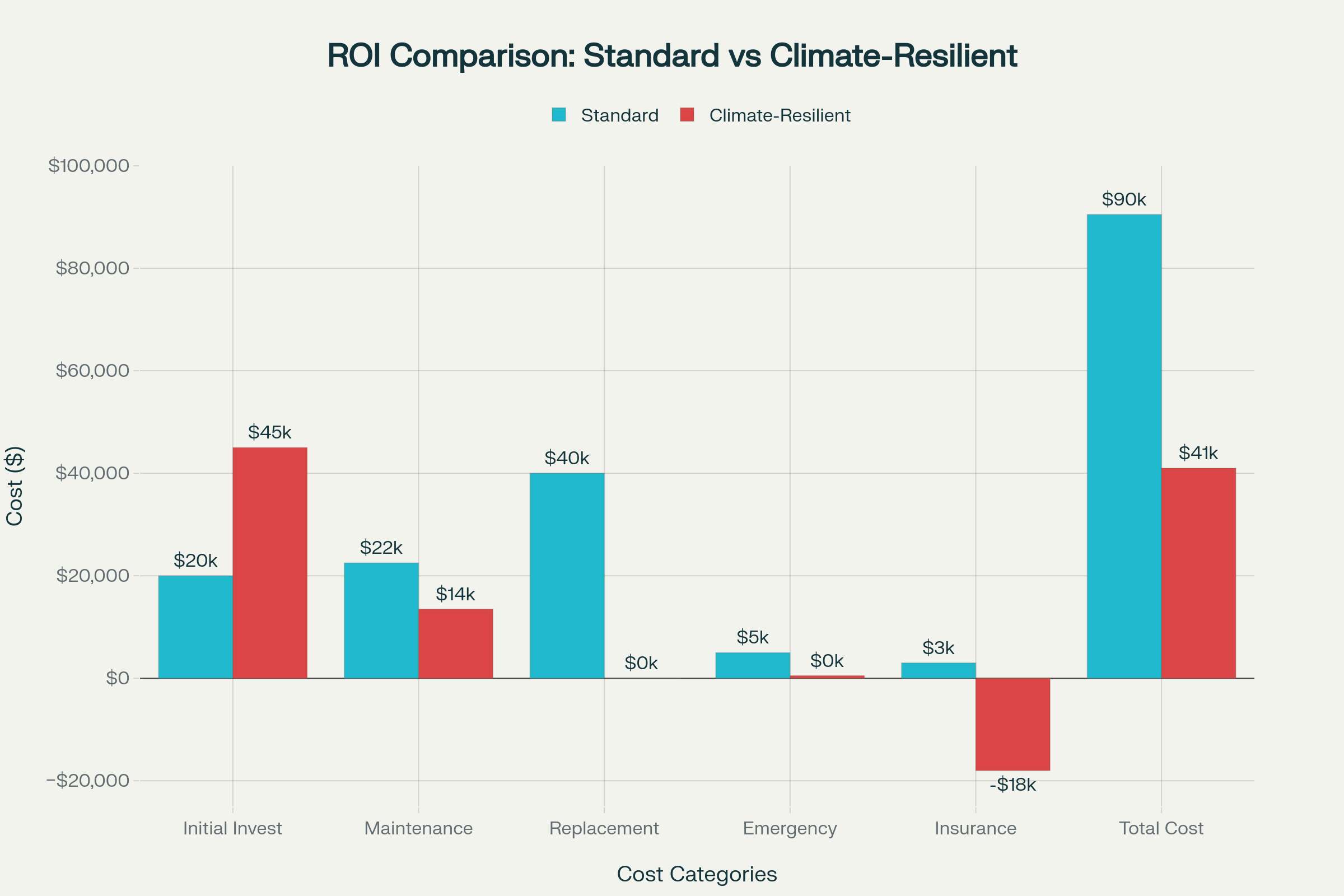

Climate-Resilient Signage as Strategic Investment

Forward-thinking businesses recognize that climate-resistant signage delivers measurable ROI through multiple channels:

- Operational Continuity: Maintained visibility during disasters when customer acquisition becomes critical for survival

- Predictable Costs: Engineered systems eliminate surprise expenses through planned maintenance cycles

- Insurance Benefits: Many carriers reduce premiums 8-15% for businesses demonstrating proactive risk management

- Competitive Edge: Professional appearance during recovery periods captures customers from less-prepared competitors

ROI Comparison Standard vs climate resilient

? How do you make signage withstand extreme weather?

Answer: Through integrated engineering combining ASCE 7-compliant foundations, impact-resistant materials, waterproof electrical systems, and modular repair capabilities—all coordinated by experienced professionals like BlinkSigns.

? Ready to Assess Your Current Signage Vulnerability?

Get a free compliance assessment from BlinkSigns’ engineering team. We’ll evaluate your signage against climate standards and identify specific upgrade opportunities.

Compliance Standards That Guide Climate-Resilient Signage

Most catastrophic signage failures can be traced back to installations that don’t follow current engineering standards—making compliance essential protection, not just an upgrade.

⚡ Engineering Impact

FEMA/NIST post-storm investigations repeatedly trace catastrophic failures to improper anchorage and load-path issues; code-compliant design & installation dramatically reduce failure risk.

International Building Code (IBC) Foundation

The IBC provides baseline requirements that climate-resilient signage must exceed:

- Structural Load Calculations: All signage must withstand specified wind, seismic, and environmental loads based on geographic risk assessment

- Foundation Engineering: Deep foundation requirements with soil analysis and anchor systems preventing uplift during extreme events

- Electrical Safety Integration: Weatherproof signage systems with surge protection and emergency shutdown capabilities

ASCE 7 Wind Load Engineering

ASCE 7 standards define precise calculations determining signage structural requirements:

- Basic Wind Speed Mapping: Per ASCE 7-16/22, Risk Category II basic wind speeds range from ~115 to 180 mph across the U.S., with the highest values in coastal South Florida.

- Exposure Classifications: Open terrain, suburban, and urban categories affecting pressure calculations and structural demands

- Importance Factors: Critical facilities requiring enhanced resistance beyond standard commercial applications

FEMA Flood Zone Compliance

FEMA regulations mandate specific protections for signage in flood-prone areas:

- Elevation Requirements: Minimum heights above Base Flood Elevation (BFE) with waterproof mounting systems

- Utility Protection: Electrical components positioned above flood levels with automatic shutdown systems

- Substantial Damage Prevention: Engineering prevents flood damage from triggering expensive compliance upgrades

Seismic Design Integration

Earthquake-prone regions require specialized engineering combining seismic resistance with weather protection:

- Flexible Connection Systems: Mounting allowing controlled movement without structural failure

- Damping Technology: Vibration control protecting both sign structures and building attachment points

- Multi-Hazard Design: Comprehensive engineering addressing simultaneous risks like earthquakes during storms

?What compliance standards guide weather resistant signage?

Answer: IBC structural requirements, ASCE 7 wind load calculations, FEMA flood compliance, and seismic design standards—all requiring professional engineering coordination that BlinkSigns provides nationwide.

Environmental Challenges That Test Signage Performance

Modern signage faces complex environmental stressors that traditional approaches cannot adequately address. Understanding these challenges enables proper engineering responses.

Storage signage under environmental Challenges

High Winds & Hurricane Resistance

Hurricane-force winds create multiple destructive forces challenging every aspect of signage design:

- Wind Pressure Dynamics: In hurricane-prone regions, ASCE 7 design pressures for components and cladding routinely reach 60–100 psf, and can exceed that on small, highly stressed elements.

- Uplift Engineering: Foundation systems resisting forces that can lift inadequately anchored signs completely from the ground

- Debris Impact Protection: Hurricane winds transform everyday objects into high-velocity projectiles, threatening sign faces and structures

- Fatigue Resistance: Extended hurricane exposure creates cyclic loading that causes progressive failure in poorly designed systems

Flood Resistance & Water Protection

Water infiltration during floods causes immediate damage and long-term degradation extending beyond flood periods:

- Waterproof Enclosures: Electrical components requiring submersion-rated protection, maintaining integrity under hydrostatic pressure

- Drainage Integration: Systems preventing water accumulation in structures and around foundation elements

- Corrosion Prevention: Floodwater containing salt, chemicals, and debris accelerates metal component degradation

- Emergency Safety Systems: Automated shutdown during flood conditions, protecting components for rapid restoration

Snow Loads & Freeze-Thaw Cycles

Winter conditions create unique stresses through accumulated weight and thermal cycling:

- Snow Load Engineering: Many northern U.S. jurisdictions adopt ASCE 7 ground snow loads ≥50 psf, which informs structural and connection design for signage

- Ice Accumulation Impact: Freezing rain creates additional weight while changing aerodynamic properties

- Thermal Expansion Management: Temperature cycling causes materials to expand and contract at different rates

- Foundation Frost Protection: Design preventing frost heave that shifts or destabilizes sign structures

Heat, UV & Solar Radiation

Extreme heat and solar intensity cause material degradation and electronic failures:

- UV Protection Systems: Advanced coatings preventing plastic degradation and color fading

- Thermal Management: Electronic component cooling, preventing LED performance loss and premature failure

- Heat Expansion Control: Engineering manages material expansion, preventing stress concentrations

- Solar Intensity Resistance: Desert and high-altitude protection exceeding standard testing parameters

Seismic Resistance & Ground Movement

Earthquake zones require specialized engineering allowing controlled movement while maintaining integrity:

- Flexible Foundation Design: Systems allowing controlled movement, preventing rigid connection failures

- Seismic Isolation Technology: Advanced installations decouple structures from ground motion

- Multi-Direction Loading: Engineering analysis addressing simultaneous forces from multiple directions

- Post-Earthquake Assessment: Design facilitating rapid inspection and restoration, minimizing disruption

Material Choices That Maximize Climate Durability

Advanced material science enables signage performance exceeding traditional approaches by decades through strategic selection and application.

Material Choices That Maximize Climate Durability

? Performance Advantage

Corrosion-resistant, marine-grade systems significantly extend service life—galvanized or epoxy-coated steel can endure 15–55 years compared to just 2–5 years for uncoated alternatives, meaning 300–1000% improved durability.

Advanced Metal Systems

Modern alloys and treatments provide exceptional durability in challenging environments:

- Marine-Grade Aluminum (5052/6061): Superior corrosion resistance, maintaining structural strength and fabrication flexibility

- 316-Grade Stainless Steel: Exceptional corrosion resistance in coastal and industrial environments where standard materials fail

- Ceramic-Enhanced Powder Coating: Multi-layer systems providing UV protection and corrosion resistance, extending life 300-500%

- Galvanic Isolation: Proper material combinations prevent corrosion where dissimilar metals contact

High-Performance Plastics & Composites

Advanced polymers combine lightweight properties with exceptional durability:

- Engineering-Grade Polycarbonate: Impact resistance 200x greater than glass while maintaining optical clarity and UV stability

- Aluminum Composite Panels: Polymer cores providing flatness, thermal stability, and fabrication flexibility

- Cast Acrylic Systems: UV-stabilized formulations maintaining properties through decades of solar exposure

- HDPE Substrates: Chemical resistance and dimensional stability for harsh industrial environments

Sustainable Weather-Resistant Materials

Environmental responsibility meets climate resilience through advanced sustainable materials:

- Recyclable Aluminum Systems: Full recyclability with indefinite reuse potential, supporting the circular economy

- Bio-Based Polymers: Weather resistance equivalent to petroleum-based materials with reduced carbon footprint

- Low-VOC Coating Systems: Water-based formulations eliminating volatile compounds while providing superior durability

- LEED Compliance Integration: Material selection supporting certification through recycled content and regional sourcing

? What materials are best for climate-resilient signage?

Answer: Marine-grade aluminum alloys, engineering-grade polycarbonate, and sustainable composites with ceramic-enhanced protective coatings—customized by BlinkSigns based on specific environmental challenges and performance requirements.

Engineering Solutions for Extreme Weather Performance

Adequate climate-resilient signage needs careful engineering that solves structural, environmental, and operational issues with better solutions than regular methods.

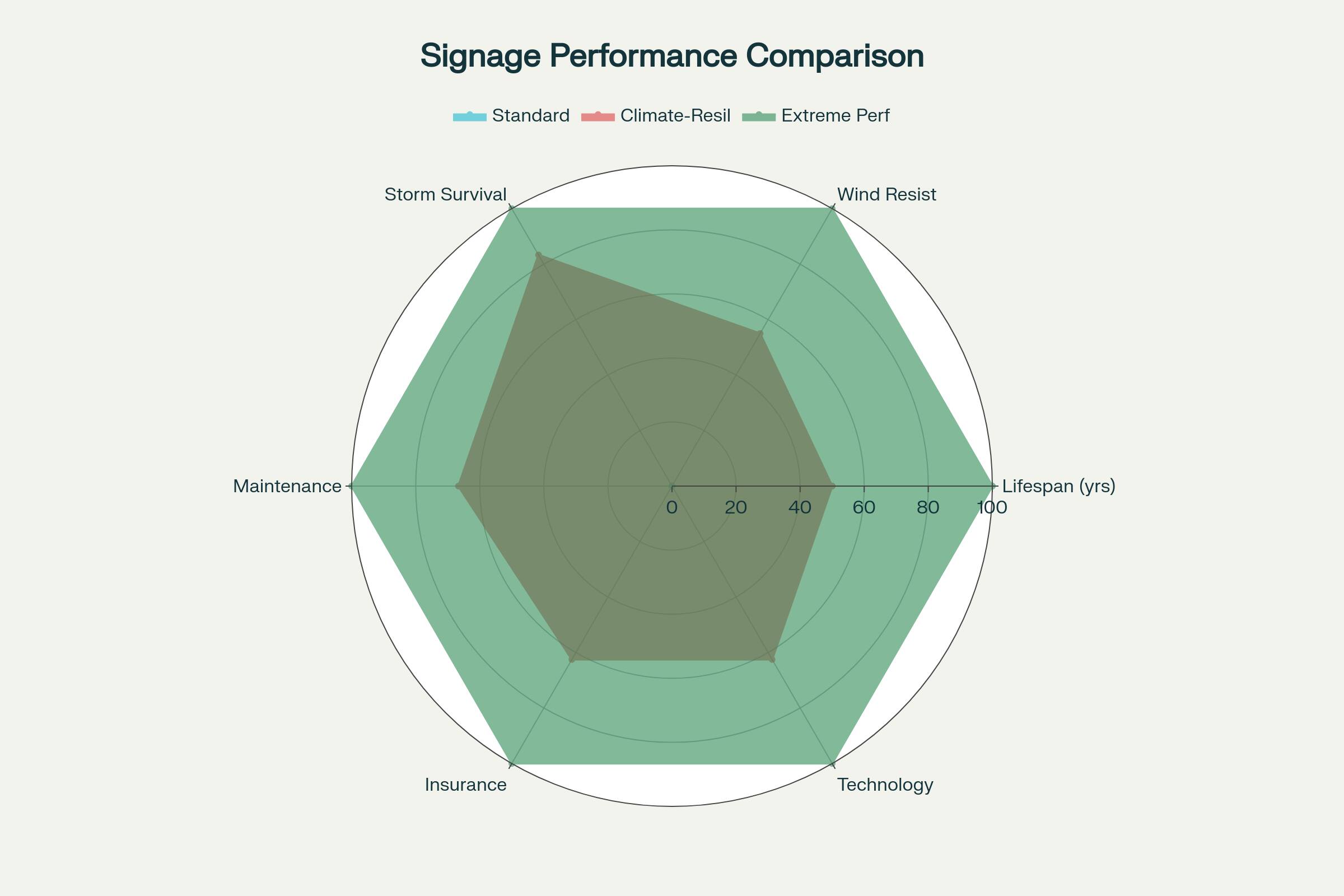

Signage Performance Comparison

Structural Design & Foundation Systems

Deep foundation engineering forms the backbone of climate resilience, requiring systems extending below frost lines while providing resistance to forces exceeding 150 pounds per square foot during extreme events.

- ASCE 7-Compliant Foundations: Engineered anchor systems preventing uplift during hurricane-force winds

- Seismic Isolation Bases: Allowing controlled movement without structural failure during earthquakes

- Multi-Point Load Distribution: Preventing stress concentrations during extended storm exposure

- Modular Designs: Enabling reinforcement as climate conditions intensify over time

Protective Coatings & Surface Treatments

Advanced surface protection systems extend operational life by 300-500% through scientifically formulated treatments:

- Ceramic-Enhanced Powder Coating: Providing UV and impact resistance with extended durability

- Hydrophobic Nanotechnology: Creating self-cleaning surfaces that shed water and debris

- Sacrificial Anode Systems: Preventing corrosion when protective layers are compromised

- Marine-Grade Formulations: Withstanding salt spray and industrial pollutants

Waterproofing & Electrical Protection

Illuminated signage requires fail-safe electrical systems to maintain safety during extreme weather:

- IP67-Rated Protection: Complete submersion-rated enclosures maintain integrity under pressure

- Multi-Stage Surge Protection: Defending against lightning and grid fluctuations

- Automated Shutdown Systems: Protecting components during flood conditions

- Redundant Power Designs: Solar backup maintains operation during outages

Modular & Rapid-Repair Systems

Speed matters when weather strikes. Advanced systems minimize downtime through strategic design:

- Quick-Response Components: Enabling pre-storm removal and post-event replacement

- Standardized Connections: Supporting universal hardware and rapid repairs

- Emergency Protocols: Reducing restoration time from days to hours

- Pre-Positioned Inventories: Ensuring immediate component availability

? How do you make signage stormproof?

Answer: Using strong foundations suited for the area, materials that can withstand impacts, waterproof electrical systems, and designs that allow quick repairs—all managed by skilled experts.

Technology That Powers Climate-Resilient Signage

Innovative technology transforms signage from passive displays into intelligent systems, optimizing performance while predicting maintenance needs before failures occur.

? Smart Monitoring Benefits

IoT-enabled predictive maintenance typically reduces maintenance costs by 20–30% and cuts unplanned failures by up to 70–75%

IoT-Enabled Environmental Monitoring

Real-time monitoring provides early warning capabilities, protecting investments through proactive intervention:

- Smart Sensor Integration: Wind speed, vibration, temperature, and humidity tracking

- Predictive Analytics: Machine learning algorithms forecasting component failure timing

- Automated Alert Systems: Notifying managers before visibility is compromised

- Performance Optimization: Adjusting operations based on environmental conditions

Advanced LED & Power Resilience

Military-grade components maintain consistent performance through extreme environmental conditions:

- Extended Temperature Range LEDs: (-40°F to +185°F) maintaining brightness and color

- Solar Integration: Intelligent battery management providing grid independence

- Smart Dimming Systems: Adjusting intensity based on ambient conditions

- Thermal Management: Preventing performance degradation in extreme heat

? Performance Data:

DOE notes quality LEDs commonly achieve L70 at ~50,000–100,000 hours with proper thermal design—supporting long outdoor lifetimes.

Remote Monitoring & Predictive Analytics

Cloud-based management enables comprehensive oversight across multiple locations:

- Real-Time Dashboards: Tracking performance across entire signage portfolios

- AI-Powered Diagnostics: Identifying potential issues before customer impact

- Mobile Applications: Enabling facility managers to monitor from anywhere

- API Integration: Connecting with existing facility management platforms

Industry Applications for Climate-Resilient Signage

Different industries face unique climate challenges requiring specialized engineering approaches and performance standards.

Industry Applications for Climate-Resilient Signage

Retail & Quick-Service Restaurants

Challenge: High-traffic locations requiring maximum uptime during recovery periods when customer patterns shift dramatically.

BlinkSigns Solution:

- Modular pylon and monument systems with redundant illumination

- Rapid-repair capabilities ensure continuous operation

- Standardized components across multiple locations

? Signage influences behavior:

76% of consumers have entered a store because of its signs, and 60% have failed to find a business due to poor/hidden signage.

Healthcare & Educational Facilities

Critical Requirements:

- Mission-critical wayfinding must remain functional during emergencies

- ADA compliance requirements during power outages

- Straightforward navigation is essential for safety and emergency response

BlinkSigns Solution:

- Redundant power systems with photoluminescent backup displays

- Seismic-resistant mounting ensures operation during infrastructure failures

- Battery backup systems maintain illumination for more than 90 minutes

Hospitality & Resort Properties

Unique Challenges:

- Coastal locations requiring premium aesthetic presentation

- Extreme environmental exposure while maintaining luxury brand positioning

- Salt air corrosion is affecting traditional signage materials

BlinkSigns Approach:

- Marine-grade materials with concealed mounting systems

- Premium finishes provide durability without compromising visual appeal

- Regular maintenance programs preserve brand image

Transportation & Municipal Infrastructure

Public Safety Requirements:

- Signage must remain functional during emergency conditions

- Critical information flow during disaster response operations

- Reliability supporting emergency evacuation procedures

Engineering Solutions:

- Fail-safe systems with multiple power sources

- Impact-resistant construction ensures operation during infrastructure damage

- Emergency communication capabilities integrated into signage systems

? Which industries need stormproof signage most?

Answer: Healthcare, retail, hospitality, and transportation sectors rely heavily on climate-resilient signage for operational continuity, safety compliance, and customer service during extreme weather events.

Predictive Comprehensive Climate-Resilient Signage Performance Comparison

| Performance Factor | Standard Signage | Climate-Resilient | Extreme Performance | Business Impact |

| Expected Lifespan | 5–7 years | 12–15 years | 20+ years | Reduced replacement cycles |

| Wind Resistance | 70–90 mph | 120–150 mph | 180+ mph (Category 5) | Storm survival capability |

| Foundation Type | Surface/shallow mount | Engineered deep foundation | Seismic isolation system | Structural integrity |

| Electrical Rating | Basic weatherproof | IP65 rated | IP67 submersion rated | Water damage prevention |

| Maintenance Frequency | Monthly/quarterly | Bi-annual inspection | Annual service | Predictable cost structure |

| Storm Survival Rate | 40–60% | 85–95% | 98%+ | Business continuity |

| Insurance Benefits | None available | Premium discounts | Risk reduction credits | Cost savings |

| Technology Integration | Basic illumination | IoT monitoring | Full predictive analytics | Performance optimization |

| Upgrade Capability | Complete replacement | Modular components | Future-proof design | Investment protection |

| ESG Compliance | Standard materials | Recyclable components | LEED-certified systems | Sustainability goals |

| Initial Investment | $15,000–$30,000 | $35,000–$65,000 | $75,000–$150,000 | Capital planning |

| Total 15-Year Cost | $65,000–$120,000 | $45,000–$80,000 | $85,000–$175,000 | Total cost of ownership |

| ROI Break-Even | N/A (cost center) | 7–9 years | 8–12 years | Investment timeline |

Case Study: StoreLocal Storage—Sustainable Signage Solutions

Client Challenge

StoreLocal Storage needed enhanced brand visibility and customer wayfinding while maintaining environmental responsibility and cost efficiency in their signage upgrade.

StoreLocal Storage—Sustainable Signage Solutions

BlinkSigns’ Climate-Conscious Approach

- LED Illuminated Signage: Energy-efficient lighting systems reduce power consumption and operational costs

- Durable ACM Panel Construction: Digitally printed and laminated panels engineered for longevity and resilience against environmental elements

- Sustainable Installation: Utilized existing post infrastructure, minimizing material waste and environmental impact

- Smart Wayfinding Solutions: Strategic placement optimizing customer flow while reducing maintenance requirements

Engineering & Sustainability Features

- Weather-Resistant Design: ACM panels selected for superior durability against Ohio weather conditions

- Energy Efficiency: LED technology provides a 50,000+ hour lifespan with minimal maintenance

- Waste Reduction: Reused existing structural elements, supporting circular economy principles

- Long-Term Performance: Materials chosen for extended lifecycle, reducing replacement frequency

Measurable Results

✓ Enhanced Visibility: LED signage significantly improved street presence and brand recognition

✓ Improved Navigation: Clear wayfinding streamlined customer experience and reduced confusion

✓ Environmental Benefits: Energy-efficient components and material reuse supported sustainability goals

✓ Cost Efficiency: Reduced operational costs through LED efficiency and existing infrastructure utilization

Climate Resilience Applications

This project demonstrates BlinkSigns’ approach to sustainable signage engineering—selecting materials and technologies that deliver long-term performance while minimizing environmental impact. The combination of durable ACM construction and energy-efficient LED systems represents the foundational elements of climate-conscious signage design.

Key Success Factors

- Material Engineering: ACM panels chosen for weather resistance and longevity

- Energy Optimization: LED systems reduce both costs and environmental impact

- Resource Efficiency: Creative reuse of existing infrastructure

- Professional Installation: Quality execution ensuring reliable long-term performance

Multi-Location Retail Chain Transformation

The challenge involves a 45-store chain that is experiencing inconsistent brand presentation as a result of weather damage.

BlinkSigns Implementation: Standardized systems with regional climate customization.

Documented Outcomes:

- Extended lifespan from 6 to 14+ years average

- 40% reduction in maintenance costs

- 95% brand consistency in customer surveys

- Enhanced insurance rates through risk management

? Investment Reality

Climate-resilient signage delivers 18-25% better ROI over 15 years despite higher upfront costs.

Future-Proofing & Climate Adaptation

Climate patterns continue intensifying, requiring adaptive design strategies addressing evolving conditions:

ESG Integration & Corporate Sustainability

Climate-resilient signage directly supports corporate environmental, social, and governance (ESG) objectives while delivering operational benefits:

- Recyclable aluminum and composite materials contribute to Materials & Resources credits

- Energy-efficient LED systems supporting Energy & Atmosphere requirements

- Low-VOC coating systems are improving Indoor Environmental Quality scores

- Regional material sourcing reduces transportation’s environmental impact

- Quantifiable carbon footprint reduction through extended product cycles

- Waste stream reduction through modular repair capabilities versus complete replacement

- Energy consumption improvements supporting Scope 2 emissions reduction goals

- Supply chain sustainability through certified material sourcing

Adaptive Engineering Features:

- Design parameters based on projected climate conditions 20-30 years forward

- Modular systems supporting emerging technologies like enhanced AI monitoring

- Upgrade pathways protecting long-term investment value

- Regulatory preparation positioning businesses ahead of evolving codes

The BlinkSigns Approach: Engineering Excellence for Extreme Performance

At BlinkSigns, we deliver signage as engineered infrastructure combining advanced materials, comprehensive engineering, and intelligent technology for reliable performance regardless of environmental challenges.

Comprehensive Service Integration

Design-Build Excellence:

- Detailed environmental risk assessment and site-specific engineering

- Advanced CAD modeling and finite element analysis, ensuring optimal performance

- Regulatory navigation and permitting coordination across all jurisdictions

- Performance validation through comprehensive testing protocols

Technology Leadership:

- IoT monitoring and predictive analytics integration

- Continuous innovation in materials and manufacturing processes

- Sustainability commitment through LEED-compliant systems

- Future-ready design with upgrade pathways

Long-Term Partnership:

- Customized maintenance programs based on environmental exposure

- 24/7 emergency response capabilities for rapid restoration

- Performance monitoring and optimization recommendations

- Comprehensive warranty protection throughout the system lifecycle

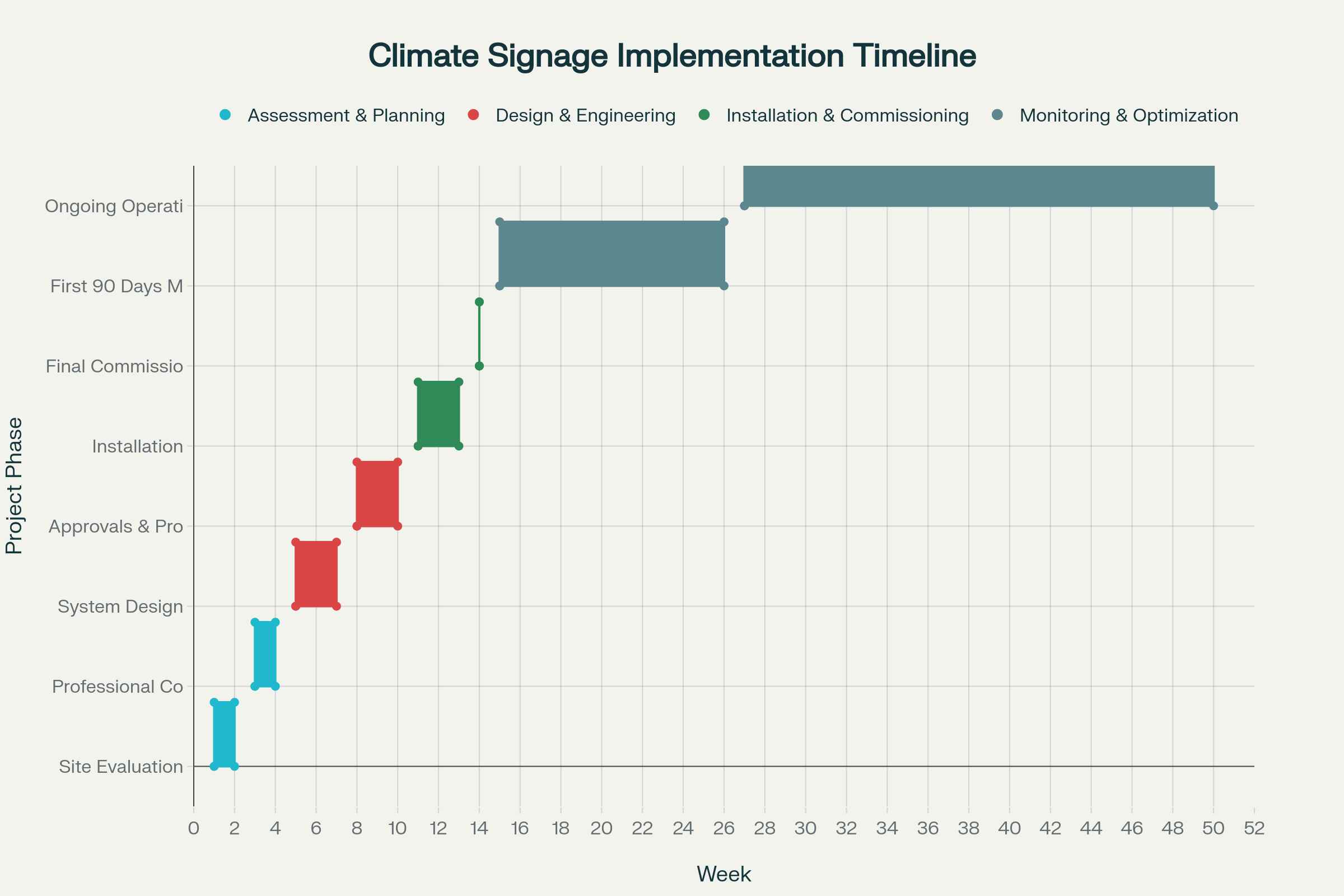

14-Week Climate-Resilient Signage Implementation Timeline

FAQs: Climate-Resilient Signage

Q: How do you make signage stormproof?

A: By using strong foundations that can handle ASCE 7 wind loads, materials that resist impacts, waterproof electrical systems, and repair options that can be easily managed

Q: What materials last longest in extreme weather?

A: Marine-grade aluminum alloys, engineering-grade polycarbonate, and ceramic-enhanced protective coatings provide optimal durability in challenging conditions.

Q: Can LED signs handle extreme heat and cold?

A: Yes—military-grade LEDs with thermal management maintain performance from -40°F to +185°F with proper system design.

Q: Do signs need different foundations in hurricane zones?

A: Absolutely—hurricane zones require deep foundations with engineered resistance to uplift, overturning, and lateral forces exceeding 150 pounds per square foot.

Q: How long do climate-resilient signs typically last?

A: 12-15 years with appropriate maintenance—typically double the standard signage lifespan in similar conditions.

Q: What’s the difference between hurricane-rated and standard signage?

A: Hurricane-rated signage follows ASCE 7 standards and uses strong materials that can resist impacts, has waterproof electrical systems, and is built on specially designed foundations

Q: Can existing signs be upgraded for weather resistance?

A: Many installations can be enhanced through foundation reinforcement, protective coatings, improved electrical systems, and impact-resistant materials.

Q: How does BlinkSigns ensure durability across different climates?

A: Through customized engineering, material selection, and protective systems based on specific environmental challenges, weather history, and projected climate changes.

Conclusion: Engineered Signage for an Uncertain Climate

Extreme weather is the new operational reality—and signage must be engineered accordingly. Traditional approaches put businesses at risk of brand damage, safety hazards, and unnecessary replacement costs, which proper engineering can prevent.

BlinkSigns delivers climate-resilient signage solutions for performance, compliance, and measurable ROI. From advanced materials and structural engineering to intelligent monitoring and comprehensive service support, we provide signage that maintains a professional appearance and full operational capability regardless of environmental challenges.

The choice is clear: reactive repairs and recurring damage, or proactive engineering that protects your brand investment through decades of reliable performance.

Protect Your Brand Investment Against Every Forecast

Your signage represents your business every day, in every condition. Make sure it’s engineered to succeed when others fail.

Ready to implement climate-resilient signage? BlinkSigns’ comprehensive approach ensures your brand maintains professional visibility and customer attraction regardless of environmental challenges.